Jan . 26, 2025 04:34 Back to list

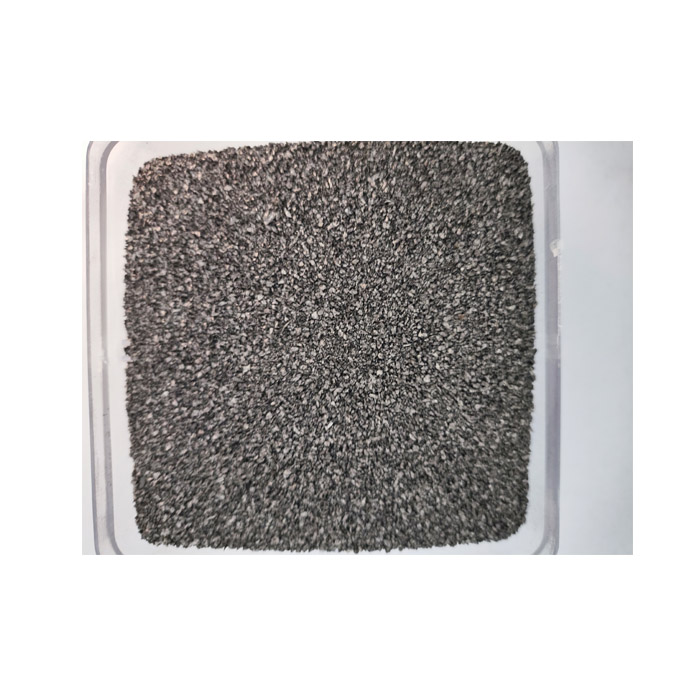

concrete aggregate

Concrete aggregate plays a pivotal role in the construction industry, forming the backbone of modern structural designs. This essential component not only enhances the structural integrity of concrete but also influences its durability, workability, and overall performance. As a professional with years of hands-on experience working with construction materials, I can share insights into the multifaceted uses and importance of concrete aggregate.

Trustworthiness in concrete aggregate sourcing involves ensuring the material's compliance with industry standards and environmental regulations. The American Society for Testing and Materials (ASTM) and American Concrete Institute (ACI) have established stringent guidelines that govern the quality of aggregates. Compliance with these standards not only guarantees the safety and durability of structures but also enhances the reputation of construction firms in the market. Product innovation in the realm of concrete aggregates continues to evolve, driven by technological advancements. Today's aggregates can be engineered and modified for specific functional requirements such as increased thermal performance or acoustic insulation. Lightweight aggregates, for example, are utilized in constructing thermally efficient buildings, reducing energy costs over the building's lifecycle. Acoustic aggregates contribute to noise reduction, a critical feature in urban construction projects. Finally, effective aggregate storage and handling is paramount to maintaining product quality during construction. Proper storage techniques prevent moisture absorption and contamination, ensuring the integrity of the concrete mix. On-site training for handling and testing aggregates enriches the crew's understanding, ensuring the successful application of high-quality concrete solutions. In conclusion, the strategic selection and application of concrete aggregates significantly impact the quality, sustainability, and performance of construction projects. As the industry progresses, ongoing education and adherence to quality standards ensure that professionals utilize these materials to their fullest potential, thus building a future that stands the test of time.

Trustworthiness in concrete aggregate sourcing involves ensuring the material's compliance with industry standards and environmental regulations. The American Society for Testing and Materials (ASTM) and American Concrete Institute (ACI) have established stringent guidelines that govern the quality of aggregates. Compliance with these standards not only guarantees the safety and durability of structures but also enhances the reputation of construction firms in the market. Product innovation in the realm of concrete aggregates continues to evolve, driven by technological advancements. Today's aggregates can be engineered and modified for specific functional requirements such as increased thermal performance or acoustic insulation. Lightweight aggregates, for example, are utilized in constructing thermally efficient buildings, reducing energy costs over the building's lifecycle. Acoustic aggregates contribute to noise reduction, a critical feature in urban construction projects. Finally, effective aggregate storage and handling is paramount to maintaining product quality during construction. Proper storage techniques prevent moisture absorption and contamination, ensuring the integrity of the concrete mix. On-site training for handling and testing aggregates enriches the crew's understanding, ensuring the successful application of high-quality concrete solutions. In conclusion, the strategic selection and application of concrete aggregates significantly impact the quality, sustainability, and performance of construction projects. As the industry progresses, ongoing education and adherence to quality standards ensure that professionals utilize these materials to their fullest potential, thus building a future that stands the test of time.

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025