Nov . 25, 2024 12:05 Back to list

Exploring ESR RF2 Graphite Manufacturing Processes and Industry Applications

The Emergence of ESR RF2 Graphite Factories A New Dawn in Material Science

In recent years, the demand for high-purity graphite has surged, driven by its applications in various industries including electronics, energy, and manufacturing. Among the most innovative advancements in this sector is the rise of Electric Arc Furnace (EAF) and Residual Fuel 2 (RF2) graphite production technologies. These methods are revolutionizing graphite manufacturing by enhancing material quality and production efficiency.

The Emergence of ESR RF2 Graphite Factories A New Dawn in Material Science

One of the primary advantages of ESR RF2 graphite factories is their ability to produce ultra-high purity graphite. This is particularly crucial for industries like semiconductor manufacturing, where the quality of materials can significantly influence device performance and longevity. The purity levels achieved through these advanced processes minimize impurities that could compromise electrical and thermal properties, ensuring that the final products meet stringent industry standards.

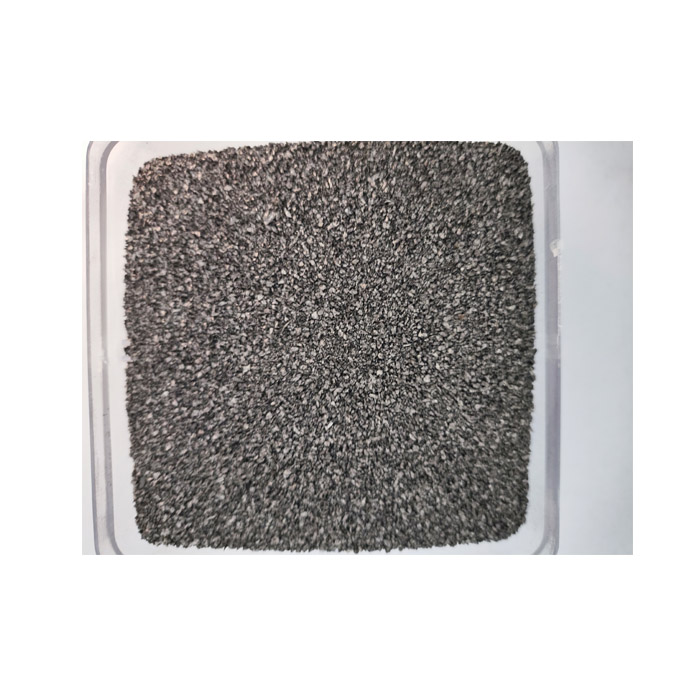

esr rf2 graphite factories

Moreover, ESR RF2 graphite has found a prominent place in the energy storage sector, particularly in lithium-ion batteries. As the demand for sustainable energy solutions continues to rise, the need for efficient battery materials has never been greater. ESR RF2 graphite, with its exceptional electrochemical properties, plays a vital role in enhancing battery performance and longevity. It is increasingly used in anodes, where its high conductivity and stability lead to faster charging times and improved overall efficiency.

Environmental considerations also play a significant role in the emergence of ESR RF2 graphite factories. Traditional graphite production methods often involve significant emissions and energy consumption. However, the innovations in EAF and RF2 technologies are designed to be more environmentally friendly. By optimizing energy usage and reducing waste, these factories align with the global push toward sustainable manufacturing practices.

In conclusion, the development of ESR RF2 graphite factories signifies a pivotal moment in material science. By combining advanced processing technologies with a focus on purity and sustainability, these factories are set to meet the growing demands of various industries while paving the way for innovations in energy storage and electronics. As we look ahead, the impact of ESR RF2 graphite is poised to redefine standards across multiple sectors, enhancing both performance and sustainability in our technological landscape.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025