Jan . 20, 2025 14:39 Back to list

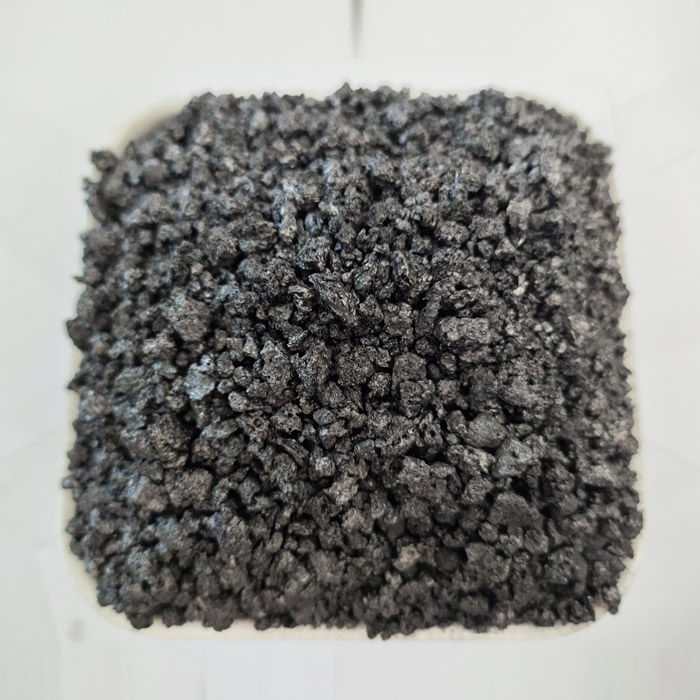

Ferro-Carbon Ball For Bof

Ladle steel making is a pivotal process in modern metallurgy, offering a significant enhancement to the quality and properties of steel. As a specialized step that occurs after initial steel production, it is integral to refining and alloying, ensuring that the final product meets stringent standards required for various industrial applications.

The authoritativeness of ladle steel making as a process is underscored by the incorporation of cutting-edge technology and rigorous quality assurance protocols. Facilities equipped with state-of-the-art ladle furnaces are able to execute complex metallurgical treatments that are beyond the capabilities of basic primary steelmaking processes. These facilities usually operate in compliance with international standards such as ISO and ASTM, which prescribe stringent guidelines for quality, safety, and environmental impact. Such compliance is a testament to the credibility and reliability of ladle steel making operations in producing high-grade steel. Trustworthiness in ladle steel making is built through the consistent production of steel that meets or exceeds the specified mechanical properties and resilience required for end-use. This reliability is paramount, especially when the steel produced is destined for safety-critical components. By maintaining a steadfast commitment to quality and precision, manufacturers can offer products that inspire confidence among clients and stakeholders, fostering long-term partnerships based on mutual trust and performance satisfaction. Moreover, ongoing research and development in ladle metallurgy aim to broaden the horizons of steelmaking, venturing into new alloys and compounds that promise superior performance. This continuous improvement, driven by professional expertise, lays the groundwork for the future of sustainable and innovative steel production solutions. In conclusion, ladle steel making represents a blend of experience, technical expertise, authoritative processes, and trusted outcomes. Its role is not only to refine the final properties of steel but also to elevate the standards of steel production globally. Through a combination of sophisticated technology, skilled human resources, and stringent quality controls, ladle metallurgy continues to shape the future of steel as a critical material in modern society.

The authoritativeness of ladle steel making as a process is underscored by the incorporation of cutting-edge technology and rigorous quality assurance protocols. Facilities equipped with state-of-the-art ladle furnaces are able to execute complex metallurgical treatments that are beyond the capabilities of basic primary steelmaking processes. These facilities usually operate in compliance with international standards such as ISO and ASTM, which prescribe stringent guidelines for quality, safety, and environmental impact. Such compliance is a testament to the credibility and reliability of ladle steel making operations in producing high-grade steel. Trustworthiness in ladle steel making is built through the consistent production of steel that meets or exceeds the specified mechanical properties and resilience required for end-use. This reliability is paramount, especially when the steel produced is destined for safety-critical components. By maintaining a steadfast commitment to quality and precision, manufacturers can offer products that inspire confidence among clients and stakeholders, fostering long-term partnerships based on mutual trust and performance satisfaction. Moreover, ongoing research and development in ladle metallurgy aim to broaden the horizons of steelmaking, venturing into new alloys and compounds that promise superior performance. This continuous improvement, driven by professional expertise, lays the groundwork for the future of sustainable and innovative steel production solutions. In conclusion, ladle steel making represents a blend of experience, technical expertise, authoritative processes, and trusted outcomes. Its role is not only to refine the final properties of steel but also to elevate the standards of steel production globally. Through a combination of sophisticated technology, skilled human resources, and stringent quality controls, ladle metallurgy continues to shape the future of steel as a critical material in modern society.

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025