Jan . 28, 2025 02:46 Back to list

tundish covering agent supplier

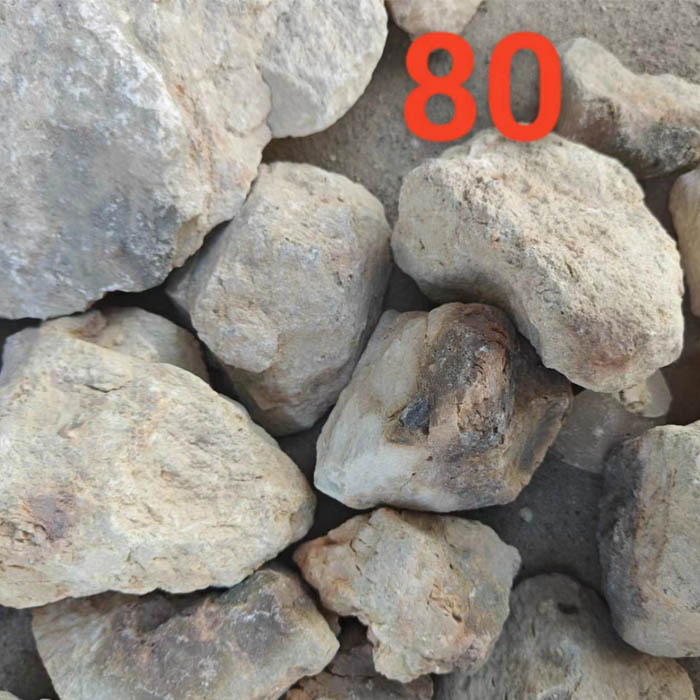

Lightweight concrete aggregates play an integral role in modern construction, offering a versatile and efficient alternative to traditional building materials. This innovative product significantly optimizes structural integrity, reduces building weight, and enhances energy efficiency. Here, we delve into the composition, benefits, applications, and expert insights on lightweight concrete aggregates to provide a comprehensive guide that underscores their importance in the construction industry.

Innovations in the manufacturing processes of lightweight concrete aggregates have further expanded their applications. Construction sites globally have begun utilizing these aggregates in the production of different types of concrete, such as structural lightweight concrete, insulating concrete, and lightweight precast panels. The adaptability of these aggregates facilitates their use in prefabricated building systems, allowing for accelerated construction timelines without sacrificing quality. It's important for construction companies and builders to trust manufacturers who provide detailed specifications and standards compliance for lightweight concrete aggregates. An authoritative figure in this domain, Dr. Steven Martinez, a materials science researcher, advises the selection of aggregates that comply with ASTM standards and are certified by recognized industry bodies. This step is crucial in ensuring the consistency and reliability of the aggregates, which directly impacts the structural integrity of the building. Incorporating lightweight concrete aggregates into construction projects does raise considerations with regard to initial cost. However, industry professionals argue that the long-term benefits, including reduced transportation costs, expedited building times, and lowered operational energy expenses, outweigh these initial investments. Consequently, companies focusing on long-term sustainability and efficiency are increasingly adopting these materials as a staple in modern construction. In terms of trustworthiness, suppliers providing lightweight concrete aggregates should maintain transparency regarding their production processes, sourcing of raw materials, and any environmental impacts. By ensuring that businesses operate ethically and sustainably, stakeholders can trust that their construction materials will uphold both the physical demands and ecological responsibilities demanded by contemporary building practices. Overall, lightweight concrete aggregates represent an evolution in the building materials industry, offering remarkable improvements in construction efficiency, sustainability, and safety. For companies invested in progressive building technologies, incorporating these aggregates can revolutionize design strategies and contribute significantly to the advancement of architectural ingenuity and environmental stewardship.

Innovations in the manufacturing processes of lightweight concrete aggregates have further expanded their applications. Construction sites globally have begun utilizing these aggregates in the production of different types of concrete, such as structural lightweight concrete, insulating concrete, and lightweight precast panels. The adaptability of these aggregates facilitates their use in prefabricated building systems, allowing for accelerated construction timelines without sacrificing quality. It's important for construction companies and builders to trust manufacturers who provide detailed specifications and standards compliance for lightweight concrete aggregates. An authoritative figure in this domain, Dr. Steven Martinez, a materials science researcher, advises the selection of aggregates that comply with ASTM standards and are certified by recognized industry bodies. This step is crucial in ensuring the consistency and reliability of the aggregates, which directly impacts the structural integrity of the building. Incorporating lightweight concrete aggregates into construction projects does raise considerations with regard to initial cost. However, industry professionals argue that the long-term benefits, including reduced transportation costs, expedited building times, and lowered operational energy expenses, outweigh these initial investments. Consequently, companies focusing on long-term sustainability and efficiency are increasingly adopting these materials as a staple in modern construction. In terms of trustworthiness, suppliers providing lightweight concrete aggregates should maintain transparency regarding their production processes, sourcing of raw materials, and any environmental impacts. By ensuring that businesses operate ethically and sustainably, stakeholders can trust that their construction materials will uphold both the physical demands and ecological responsibilities demanded by contemporary building practices. Overall, lightweight concrete aggregates represent an evolution in the building materials industry, offering remarkable improvements in construction efficiency, sustainability, and safety. For companies invested in progressive building technologies, incorporating these aggregates can revolutionize design strategies and contribute significantly to the advancement of architectural ingenuity and environmental stewardship.

Next:

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025