Jan . 09, 2025 13:45 Back to list

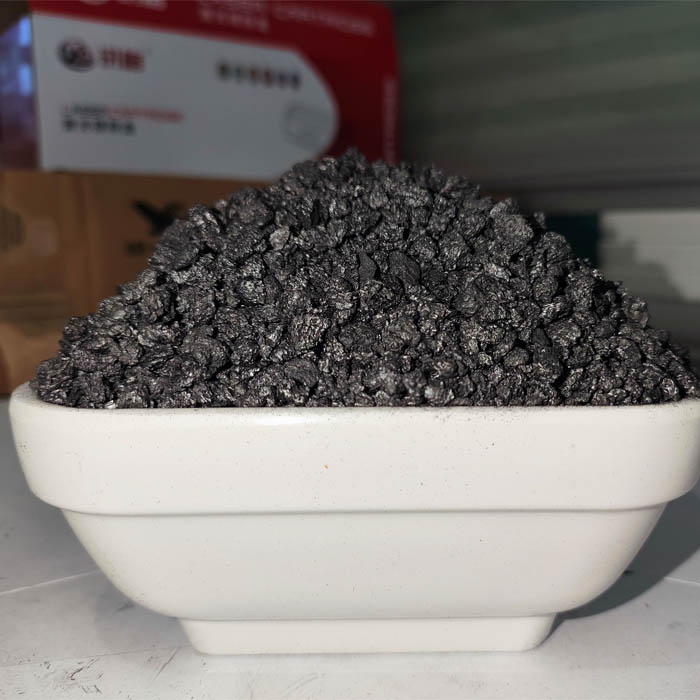

Ferro-Carbon Ball For Bof

Metallurgical materials are the backbone of modern industrial processes, serving as the foundation for countless products and applications across various sectors. Their importance cannot be overstated, as these materials are integral to the functioning and advancement of technologies that shape our daily lives. This article delves into some of the latest innovations and applications of metallurgical materials, showcasing their crucial role and advancements in today's competitive market.

As environmental considerations gain prominence, metallurgical innovations in recycling and sustainable material development are becoming focal points. The establishment of closed-loop recycling systems that recover and reprocess materials like aluminum and steel exemplifies a shift toward sustainable practices. These measures not only reduce the carbon footprint of manufacturing processes but also align with the growing consumer demand for environmentally conscious products. Leading industry players are adopting these practices, setting benchmarks for eco-friendly manufacturing, and showcasing authentic commitment to environmental stewardship. Experts in the field continuously emphasize the importance of research and development in pushing the boundaries of metallurgical sciences. The integration of machine learning and artificial intelligence in material design processes is enhancing predictive capabilities, allowing for more efficient and customized material development that meets specific industry needs. This expert-driven approach ensures that metallurgical materials stay at the cutting edge of technological advancements. Furthermore, trust in metallurgical material advancements is bolstered by stringent quality standards and certifications from authoritative bodies such as ASTM International and ISO. These standards ensure that products meet the highest levels of safety, performance, and reliability, factors that are non-negotiable in high-stakes industries such as aerospace, automotive, and healthcare. In summary, the ongoing innovations in metallurgical materials are driving significant transformations across multiple domains. The blend of experience, expertise, authority, and trust forms the cornerstone of these advancements, ensuring that metallurgical materials continue to be pivotal in shaping the industries of tomorrow. As these materials evolve, they not only promise enhancements in product performance and sustainability but also reinforce a commitment to advancing human progress responsibly and reliably.

As environmental considerations gain prominence, metallurgical innovations in recycling and sustainable material development are becoming focal points. The establishment of closed-loop recycling systems that recover and reprocess materials like aluminum and steel exemplifies a shift toward sustainable practices. These measures not only reduce the carbon footprint of manufacturing processes but also align with the growing consumer demand for environmentally conscious products. Leading industry players are adopting these practices, setting benchmarks for eco-friendly manufacturing, and showcasing authentic commitment to environmental stewardship. Experts in the field continuously emphasize the importance of research and development in pushing the boundaries of metallurgical sciences. The integration of machine learning and artificial intelligence in material design processes is enhancing predictive capabilities, allowing for more efficient and customized material development that meets specific industry needs. This expert-driven approach ensures that metallurgical materials stay at the cutting edge of technological advancements. Furthermore, trust in metallurgical material advancements is bolstered by stringent quality standards and certifications from authoritative bodies such as ASTM International and ISO. These standards ensure that products meet the highest levels of safety, performance, and reliability, factors that are non-negotiable in high-stakes industries such as aerospace, automotive, and healthcare. In summary, the ongoing innovations in metallurgical materials are driving significant transformations across multiple domains. The blend of experience, expertise, authority, and trust forms the cornerstone of these advancements, ensuring that metallurgical materials continue to be pivotal in shaping the industries of tomorrow. As these materials evolve, they not only promise enhancements in product performance and sustainability but also reinforce a commitment to advancing human progress responsibly and reliably.

Latest news

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025