Product indicators

|

Low nitrogen recarburizer |

|

|

|

|

|

|

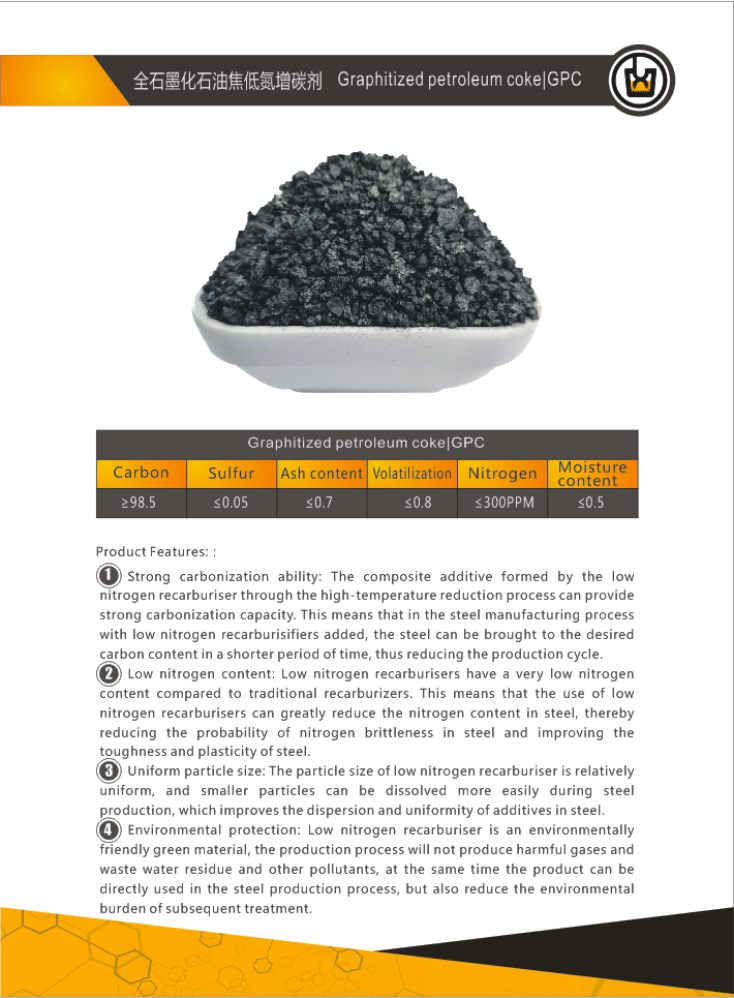

Carbon |

Sulfur |

Ash content |

Volatilization |

Nitrogen |

Moisture content |

|

≥98.5 |

≤0.05 |

≤0.7 |

≤0.8 |

≤300PPM |

≤0.5 |

Size

0-0.2mm 0.2-1mm, 1-5mm, ... or as requestEmail Graphhitized Petroleum

Packing details

1, 1ton Jumbo Bag, 18tons/20'Container

2, Bulk in Container, 20-21tons/20'Container

3, 25Kg small bags and jumbo bags,18tons/20'Container

4, As customers request

Delivery port

Tianjin or Qingdao, China

Product Features

1. Strong carbonization ability: The composite additive formed by the low nitrogen decarburise through the high-temperature reduction process can provide strong carbonization capacity. This means that in the steel manufacturing process with low nitrogen, recarburisifiers added, the steel can be brought to the desired carbon content in a shorter period of time, thus reducing the production cycle.

2. Low nitrogen content: Low nitrogen recarburisers have a very low nitrogen content compared to traditional recarburizers. This means that the use of low nitrogen decarburises can greatly reduce the nitrogen content in steel, thereby reducing the probability of nitrogen brittleness in steel and improving the toughness and plasticity of steel.

3. Uniform particle size: The particle size of low nitrogen decarburise is relatively uniform, and smaller particles can be dissolved more easily during steel production, which improves the dispersion and uniformity of additives in steel.

4. Environmental protection: Low nitrogen decarburise is an environmentally friendly green material, the production process will not produce harmful gases and wastewater residue, and other pollutants, at the same time the product can be directly used in the steel production process, but also reduce the environmental burden of subsequent treatment.

Product Usage Introduction

1. Adding method: Usually, the number of low nitrogen recarburiser is small, and it will not be directly put into the blast furnace for refining but added to the molten steel for smelting and used in the steel manufacturing process. Before adding low-nitrogen recarburisiz, the molten steel needs to be pushed out into the cooling well or insulation tank, and then the low-nitrogen recarburiser is evenly mixed with the molten steel by standing, stirring, and other methods.

2. Dosage: When using low nitrogen recarburisers, the amount of additives needs to be determined according to the requirements of steel manufacturing and specific product requirements. In general, the amount of low nitrogen recarburiser added is small compared to the mass of molten steel, usually no more than 1%. Therefore, when adding low nitrogen recarburisers, it is necessary to strictly grasp the amount and time of addition to ensure the quality of steel.

3. Temperature requirements: Low nitrogen recarburiser is mainly suitable for metallurgical processes with high molten steel temperatures. When using additives, the temperature and time of addition need to be considered to ensure that the low nitrogen recarburiser can be completely broken down and functional. Typically, low nitrogen recarburisers are added at temperatures between 1500°C and 1800°C.

4. Low nitrogen recarburiser has unique properties such as strong carbonization capacity, low nitrogen content, uniform particle size, and environmentally friendly green. This makes the product a new type of raw material for steel manufacturing and will be more widely used in the future.