Jan . 22, 2025 01:10 Back to list

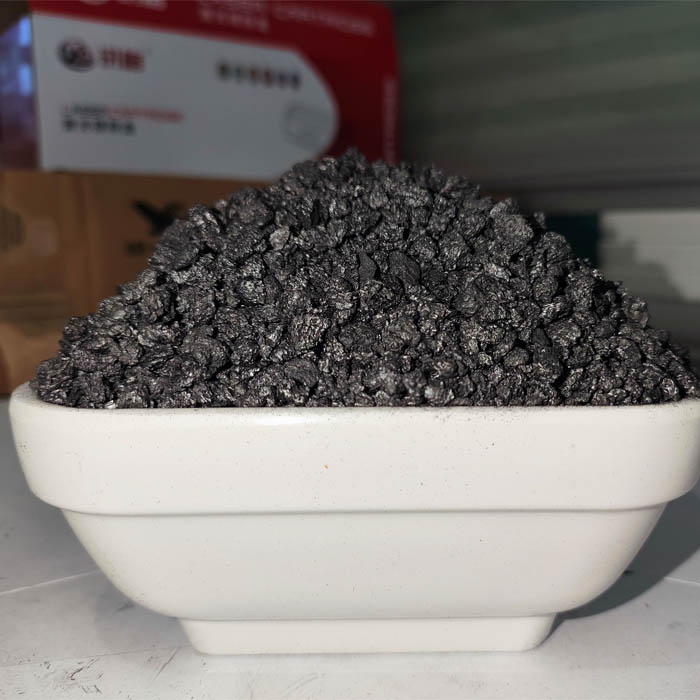

recarburizer manufacturer

Choosing the right recarburizer manufacturer is a critical decision for companies looking to enhance the quality and efficiency of their metallurgical processes. A recarburizer is an additive used in the steelmaking process to introduce carbon to the molten metal, helping achieve the desired chemical composition and mechanical properties in the final product. Here, we will delve into essential aspects of finding a credible recarburizer manufacturer, leveraging years of industry expertise and deep insights.

Trustworthiness is essential in any business relationship, and selecting a recarburizer manufacturer is no different. Transparency in operations, ethical business practices, and a customer-centric approach are pivotal in establishing trust. A trustworthy manufacturer will provide detailed product information, including sourcing raw materials, production processes, and quality control measures. Open communication channels, prompt responses to inquiries, and comprehensive support services reflect a manufacturer's dedication to customer satisfaction and trust-building. Finally, it's beneficial to consider feedback from other industry practitioners who have engaged with the manufacturer. Real-life testimonials and case studies can offer invaluable insights into the quality of the products and the manufacturer's service level. This peer-reviewed information can often be more indicative of a manufacturer’s capabilities than any marketing materials. In conclusion, selecting a recarburizer manufacturer involves evaluating their experience, expertise, authoritativeness, and trustworthiness. By doing so, companies in the metallurgy sector can ensure a higher quality of metal production, reduce operational costs, and gain a competitive edge in the market. As the steel industry continues to evolve, aligning with a manufacturer that embodies these qualities enables businesses to innovate and thrive amidst changing demands.

Trustworthiness is essential in any business relationship, and selecting a recarburizer manufacturer is no different. Transparency in operations, ethical business practices, and a customer-centric approach are pivotal in establishing trust. A trustworthy manufacturer will provide detailed product information, including sourcing raw materials, production processes, and quality control measures. Open communication channels, prompt responses to inquiries, and comprehensive support services reflect a manufacturer's dedication to customer satisfaction and trust-building. Finally, it's beneficial to consider feedback from other industry practitioners who have engaged with the manufacturer. Real-life testimonials and case studies can offer invaluable insights into the quality of the products and the manufacturer's service level. This peer-reviewed information can often be more indicative of a manufacturer’s capabilities than any marketing materials. In conclusion, selecting a recarburizer manufacturer involves evaluating their experience, expertise, authoritativeness, and trustworthiness. By doing so, companies in the metallurgy sector can ensure a higher quality of metal production, reduce operational costs, and gain a competitive edge in the market. As the steel industry continues to evolve, aligning with a manufacturer that embodies these qualities enables businesses to innovate and thrive amidst changing demands.

Latest news

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025