aug . 21, 2025 19:20 Back to list

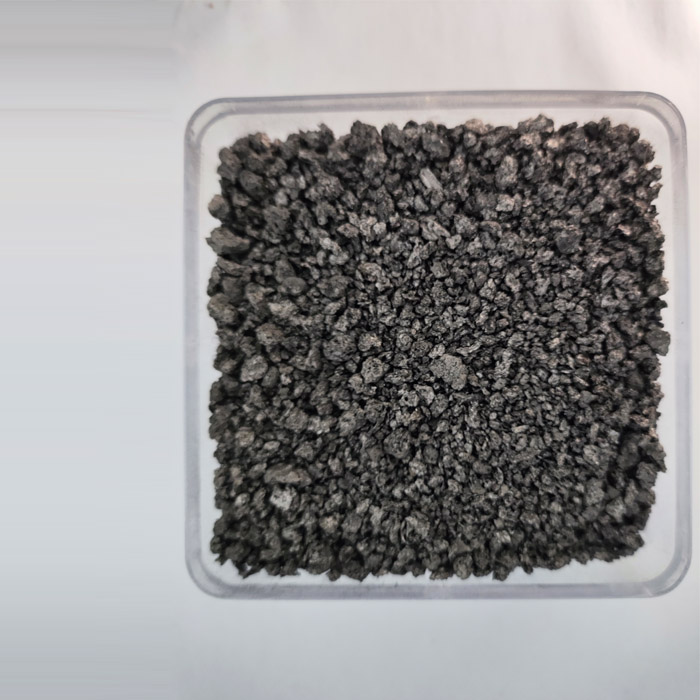

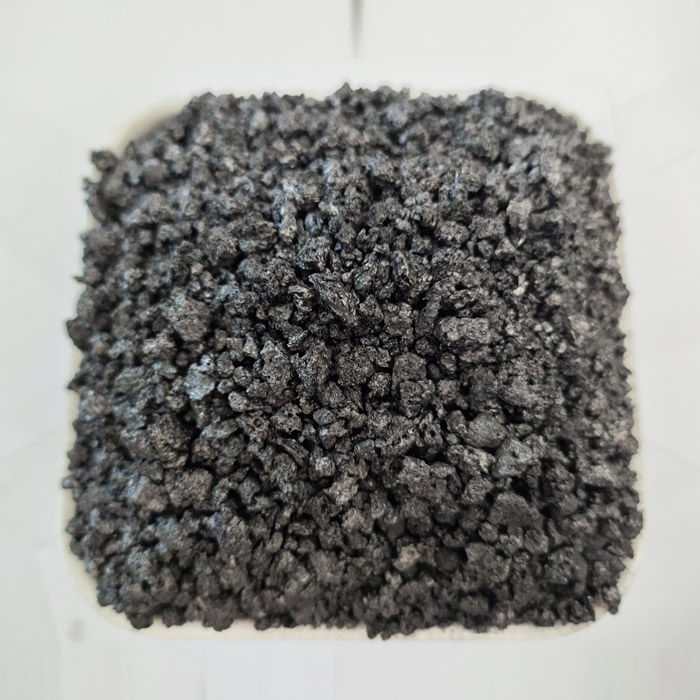

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

Navigating the Advanced World of High-Performance Recarburisers

In the demanding landscape of modern metallurgy, the quest for superior material purity and precise chemical control is paramount. Industries like steel manufacturing, foundries, and specialized alloy production are continuously seeking advanced solutions to optimize their processes, enhance product quality, and minimize environmental impact. Central to achieving these objectives is the selection of high-quality recarburising agents. Among the most advanced options available today is Graphitized Petroleum Coke/Low Nitrogen Recarburiser (GPC/LNR).

This sophisticated material represents a significant leap forward from conventional recarburisers, offering unparalleled purity, consistency, and performance. Its unique properties are derived from a meticulously controlled manufacturing process, transforming raw petroleum coke into a highly graphitized, low-nitrogen carbon source. This article delves deep into the technical intricacies, application benefits, and strategic considerations surrounding this critical metallurgical additive, providing B2B decision-makers and technical professionals with the insights needed to make informed choices for their operations.

We will explore the industry trends driving the demand for high-purity carbon, dissect the technical parameters that define superior GPC/LNR, illustrate its diverse application scenarios, highlight its distinct advantages over traditional alternatives, and offer guidance on selecting a reputable manufacturer. Furthermore, we will present compelling data, real-world application examples, and a robust framework for assessing trustworthiness, ensuring a comprehensive understanding of this indispensable material.

Understanding Graphitized Petroleum Coke/Low Nitrogen Recarburiser: A Technical Deep Dive

At its core, Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a carbonaceous material derived from petroleum coke, which undergoes intense thermal treatment at extremely high temperatures (typically above 2500°C) in a process known as graphitization. This process transforms the amorphous carbon structure of raw petroleum coke into a highly ordered, crystalline graphite structure, dramatically improving its purity, conductivity, and carbon recovery efficiency. The "Low Nitrogen" aspect signifies a further refinement to minimize nitrogen content, which is crucial for preventing nitrogen-related defects in steel and cast iron.

The superior performance of GPC/LNR stems from its unique properties:

- High Carbon Content (>98.5%): Ensures maximum carbon addition with minimal impurities.

- Low Sulfur Content ( Essential for preventing brittleness and other sulfur-induced defects in metals.

- Low Nitrogen Content ( Crucial for high-grade steels and cast irons where nitrogen can cause porosity, embrittlement, and reduced mechanical properties.

- High Graphitization Degree: Facilitates rapid dissolution and high carbon recovery in molten metal, enhancing efficiency.

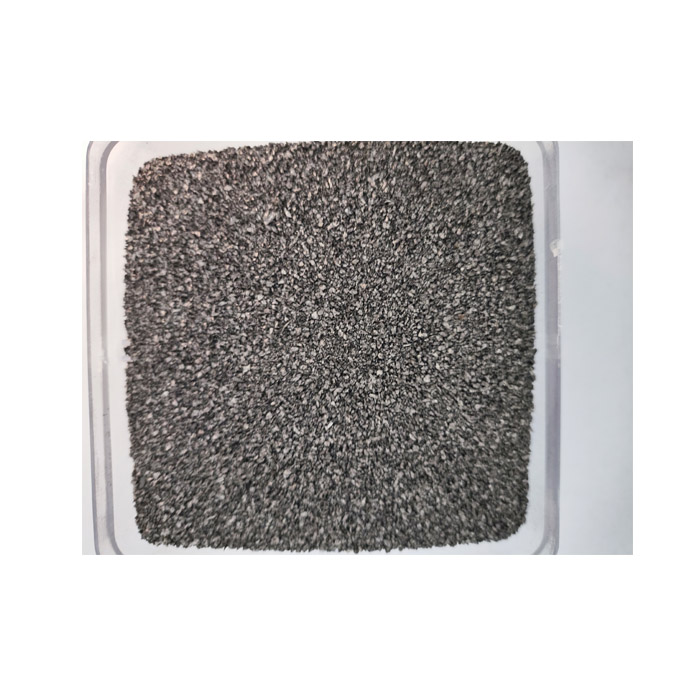

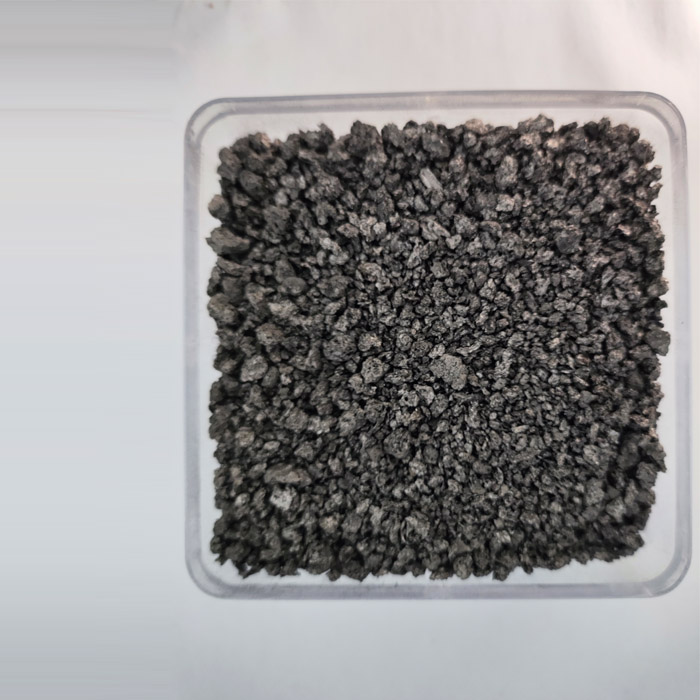

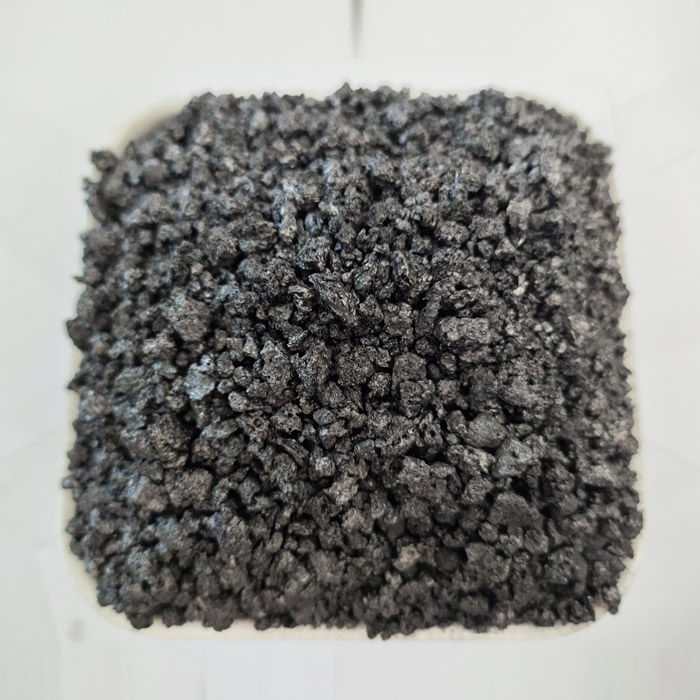

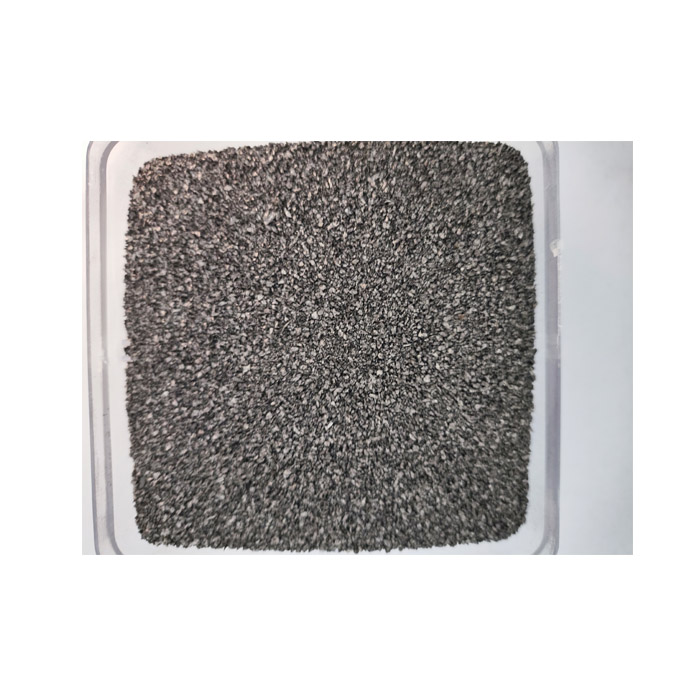

- Consistent Particle Size Distribution: Critical for controlled carbon addition and preventing dusting or segregation during handling and use.

The transformation into a graphitized material leads to improved solubility in molten metals, making it an ideal choice for precise carbon adjustments in various melting processes, including electric arc furnaces (EAFs), induction furnaces, and cupola furnaces.

Key Technical Parameters of Graphitized Petroleum Coke/Low Nitrogen Recarburiser

Understanding the specific technical parameters is vital for selecting the appropriate grade of Graphitized Petroleum Coke/Low Nitrogen Recarburiser for a given metallurgical application. Below is a typical specification table:

| Parameter | Typical Value Range | Significance |

|---|---|---|

| Fixed Carbon (FC) | > 98.5% | Indicates the effective carbon content available for carburization. Higher FC means less material needed. |

| Sulfur (S) | < 0.05% | Lower sulfur reduces the risk of hot shortness, embrittlement, and environmental emissions. |

| Nitrogen (N) | < 100 ppm (0.01%) | Crucial for preventing porosity, blowholes, and nitrogen-related defects in precision castings and high-strength steels. |

| Ash Content | < 0.5% | Represents non-combustible impurities. Lower ash reduces slag formation and contamination of the melt. |

| Volatile Matter (VM) | < 0.5% | Indicates combustible gases released upon heating. Lower VM means less smoke, better recovery, and safer handling. |

| Moisture | < 0.5% | Minimizes hydrogen pick-up in the melt and prevents splashing during addition. |

| Particle Size | 0-1mm, 1-5mm, 3-8mm, 5-10mm, etc. (customizable) | Optimized for dissolution rate and application method (e.g., ladle addition, furnace addition). |

The Manufacturing Process: From Raw Material to High-Performance Recarburiser

The production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a complex, energy-intensive process that transforms raw petroleum coke into a highly purified and crystalline carbon product. Unlike the manufacturing of metal components through casting or forging, GPC/LNR production involves a series of high-temperature thermal treatments and meticulous material handling. The primary steps include:

- Raw Material Selection: High-quality calcined petroleum coke (CPC) with low sulfur and ash content is chosen as the primary feedstock. This initial selection is critical for the final product's purity.

- Crushing and Sizing: The CPC is crushed to a specific particle size distribution to ensure uniform processing in subsequent stages.

- Graphitization Furnace Loading: The prepared coke is loaded into specialized graphitization furnaces. These are typically Acheson furnaces or similar resistance-heating furnaces capable of reaching extremely high temperatures.

- High-Temperature Graphitization (2500°C - 3000°C): This is the most crucial step. The coke is heated under controlled atmospheric conditions (often inert gas) to temperatures ranging from 2500°C to 3000°C. At these extreme temperatures, the carbon atoms rearrange from an amorphous or turbostratic structure into a highly ordered, three-dimensional graphitic crystalline lattice. This process drives off residual impurities, including sulfur and nitrogen, and significantly improves electrical and thermal conductivity, and most importantly, reactivity in molten metal.

- Cooling: After the graphitization cycle, the material is slowly cooled under controlled conditions to prevent thermal shock and maintain structural integrity.

- Post-Processing: The cooled graphitized petroleum coke is then further crushed, screened, and classified into various particle size fractions according to customer specifications. Advanced screening and dedusting technologies ensure a consistent and clean product.

- Quality Control: Throughout the entire process, stringent quality control measures are implemented. This includes chemical analysis (fixed carbon, sulfur, nitrogen, ash, volatile matter, moisture), physical testing (particle size distribution, density), and morphological examination (graphitization degree).

Detection Standards and Quality Assurance

Adherence to international standards is paramount for ensuring the quality and consistency of Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Reputable manufacturers typically follow standards such as:

- ISO 9001: For Quality Management Systems, ensuring consistent production and customer satisfaction.

- ISO 14001: For Environmental Management Systems, reflecting a commitment to sustainable practices.

- Specific ASTM Standards: For testing and analysis of carbon materials, such as ASTM D3172 (Proximate Analysis), ASTM D4239 (Sulfur content), and specialized methods for nitrogen.

The rigorous manufacturing process, coupled with strict quality control and adherence to international standards, ensures that the resulting Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a high-purity, low-impurity material, optimized for superior carbon recovery and minimal detrimental effects on the molten metal. The typical service life of such a material is directly tied to its consumption rate in metallurgical processes, but its intrinsic quality ensures stable performance throughout its use in a melt.

Applications Across Industries: Where Purity Matters

The primary application of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is in the metallurgical industry, where it serves as a critical carbon additive. Its high purity and rapid dissolution make it indispensable for processes demanding precise carbon control and low impurity levels. While the prompt mentions petrochemical, metallurgy, and water supply/drainage, the core use of GPC/LNR is overwhelmingly in high-end metallurgical applications due to its specialized nature. We will focus on these key sectors:

1. Steelmaking Industry

In electric arc furnaces (EAFs) and induction furnaces, Graphitized Petroleum Coke/Low Nitrogen Recarburiser is used to increase the carbon content of molten steel to specified levels. Carbon is a vital alloying element that imparts strength, hardness, and other mechanical properties to steel. Its low nitrogen content is particularly critical in producing advanced high-strength steels (AHSS), specialty steels, and tool steels, where nitrogen can lead to:

- Nitrogen Porosity: Formation of gas bubbles, leading to defects and reduced mechanical integrity.

- Nitride Formation: Leading to embrittlement and reduced ductility.

- Surface Defects: Compromising the aesthetic and functional quality of the final product.

The high carbon recovery rate of GPC/LNR also contributes to energy efficiency by reducing the overall amount of additive required and shortening tap-to-tap times.

2. Foundry Industry (Cast Iron Production)

For cast iron production, whether grey iron, ductile iron, or malleable iron, controlled carbon content is essential for defining microstructures, fluidity, and mechanical properties. Graphitized Petroleum Coke/Low Nitrogen Recarburiser is preferred due to its ability to dissolve quickly and cleanly in the melt, promoting uniform carbon distribution and graphitization:

- Elimination of Carbides: Helps prevent the formation of hard, brittle carbides, which can lead to machining difficulties and reduced strength.

- Improved Fluidity: Optimized carbon levels contribute to better melt fluidity, crucial for casting intricate shapes.

- Reduced Shrinkage and Porosity: Proper carbon control, particularly with low nitrogen, minimizes casting defects.

- Consistent Microstructure: Leading to predictable mechanical properties and reduced scrap rates.

The "low nitrogen" aspect is especially beneficial in ductile iron production, where excess nitrogen can interfere with spheroidal graphite formation, leading to chunky graphite and reduced mechanical properties. By using Graphitized Petroleum Coke/Low Nitrogen Recarburiser, foundries can achieve superior nodularity and consistent ductile iron quality.

3. Special Alloys and Master Alloys

For producers of high-performance alloys where precise chemical composition is critical, GPC/LNR offers the necessary purity and controlled carbon input. This includes specialized ferroalloys and other master alloys where any impurity can drastically alter the final product's characteristics.

In all these applications, the advantages extend beyond mere carbon addition. The use of high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser translates directly into improved product consistency, reduced material consumption, lower energy costs, and ultimately, a more competitive final product in the market. While applications in petrochemicals or water treatment are typically associated with other forms of carbon (e.g., activated carbon for filtration), GPC/LNR's strength lies in its metallurgical efficacy, specifically where high carbon recovery and ultra-low nitrogen are non-negotiable.

Technical Advantages and Performance Metrics

The distinct advantages of utilizing Graphitized Petroleum Coke/Low Nitrogen Recarburiser over alternative carbon sources are profound, directly impacting operational efficiency, product quality, and cost-effectiveness. These advantages are rooted in its unique structural and chemical properties:

1. Superior Carbon Recovery and Efficiency

Due to its high graphitization degree, GPC/LNR exhibits exceptional solubility and dissolution rates in molten metal. This leads to very high carbon recovery rates, often exceeding 95%. In contrast, less graphitized or amorphous carbon sources may have lower recovery, meaning more material is required to achieve the target carbon content, leading to higher consumption costs and increased slag volume. The rapid dissolution minimizes the time the furnace is open, contributing to energy savings and increased productivity (e.g., shorter tap-to-tap times in EAFs).

2. Precisely Controlled Low Nitrogen Content

The "Low Nitrogen" aspect is a critical differentiator. Nitrogen is a detrimental element in many ferrous alloys, leading to defects such as pinholes, porosity, and embrittlement. Traditional recarburisers like metallurgical coke or even ungraphitized petroleum coke can introduce significant levels of nitrogen (hundreds to thousands of ppm). By rigorously controlling nitrogen levels to below 100 ppm, Graphitized Petroleum Coke/Low Nitrogen Recarburiser prevents these issues, ensuring the integrity and mechanical properties of high-grade steels and precision castings. This is particularly vital for safety-critical components in automotive, aerospace, and energy sectors.

3. Minimal Impurities (Sulfur, Ash, Volatile Matter)

The intensive graphitization process effectively removes most of the undesirable impurities present in raw petroleum coke. The resultant low sulfur content (

4. Enhanced Melt Quality and Reduced Defects

The combination of high carbon purity, low nitrogen, and rapid dissolution directly translates into improved melt quality. It helps in achieving a more homogeneous carbon distribution within the molten metal, which is fundamental for consistent microstructure development upon solidification. This consistency reduces the likelihood of casting defects such as porosity, shrinkage, hard spots, and internal stresses, leading to fewer rejected parts and higher yields.

By using Graphitized Petroleum Coke/Low Nitrogen Recarburiser, manufacturers can:

- Optimize Production Costs: Through higher carbon recovery, reduced material consumption, and lower energy expenditure.

- Improve Product Performance: Achieve desired mechanical properties and microstructure without detrimental impurities.

- Reduce Environmental Footprint: Lower emissions and less slag generation.

- Increase Operational Stability: Predictable performance leads to fewer process adjustments and reduced downtime.

These performance metrics underscore why investing in high-grade Graphitized Petroleum Coke/Low Nitrogen Recarburiser is not merely an expense, but a strategic decision that drives long-term profitability and competitiveness in the metallurgy sector.

Choosing the Right Supplier: Manufacturer Comparison & Custom Solutions

Selecting the right supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser is as critical as understanding the product itself. The market offers various grades and qualities, and aligning with a reputable manufacturer can significantly impact your production efficiency, product quality, and supply chain reliability. Here are key factors to consider when evaluating potential partners:

1. Manufacturing Expertise and Technology

A leading manufacturer will possess state-of-the-art graphitization furnaces and advanced processing equipment. Inquire about their production capacity, process control systems, and R&D capabilities. Companies that continuously invest in technological upgrades are more likely to deliver consistent, high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Look for evidence of extensive experience in carbon material science and a deep understanding of metallurgical processes.

2. Stringent Quality Control and Certifications

Verify the supplier's quality assurance protocols. Do they have an ISO 9001 certified Quality Management System? Are their products regularly tested against international standards (e.g., ASTM)? Request recent Certificates of Analysis (CoAs) for their Graphitized Petroleum Coke/Low Nitrogen Recarburiser batches. A transparent manufacturer will readily provide documentation demonstrating their commitment to purity, consistency, and traceability.

3. Customization Capabilities

Metallurgical processes vary significantly, requiring different particle sizes, packaging, and sometimes even nuanced chemical compositions. A flexible supplier should be able to offer customized solutions for Graphitized Petroleum Coke/Low Nitrogen Recarburiser. This includes tailoring particle size distribution (e.g., 0-1mm for ladle additions, 3-8mm for furnace additions), packaging options (bulk bags, paper bags), and even specific impurity limits if required by niche applications. This adaptability can optimize your material handling and furnace integration.

4. Supply Chain Reliability and Logistics

Timely and reliable delivery is crucial for uninterrupted production. Assess the supplier's logistical capabilities, global reach, and inventory management. A strong supplier will have robust supply chain management to ensure consistent availability of Graphitized Petroleum Coke/Low Nitrogen Recarburiser and on-time delivery, minimizing costly downtime for your operations. Inquire about their typical delivery cycles and their ability to handle emergency orders.

5. Technical Support and Customer Service

Beyond product delivery, a valuable partner offers technical support. This might include assistance with product selection, optimization of addition methods, troubleshooting, and post-sales service. Companies with dedicated technical teams demonstrate a commitment to customer success and foster long-term partnerships. Check for customer testimonials and case studies that highlight their service excellence.

By systematically evaluating these aspects, B2B buyers can identify a supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser that not only meets their immediate product needs but also acts as a strategic partner, contributing to process optimization and overall business growth.

Application Cases and Success Stories

The real-world impact of high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser is best demonstrated through its successful application in various metallurgical operations. While specific client names are confidential, we can illustrate typical scenarios where its adoption has yielded significant benefits:

Case Study 1: High-Strength Steel Manufacturer

A major steel producer, focused on automotive and structural steels, faced recurring issues with nitrogen porosity in their ladle furnace operations. Despite meticulous control of other additives, high nitrogen levels persisted, leading to increased rejection rates and costly rework. Upon switching from a traditional recarburiser to a premium grade of Graphitized Petroleum Coke/Low Nitrogen Recarburiser, the immediate impact was a dramatic reduction in nitrogen pick-up in the molten steel. Within three months, their scrap rate due to nitrogen porosity dropped by 15%, and the consistency of mechanical properties improved significantly. This translated into substantial cost savings and enhanced reputation for quality.

Case Study 2: Precision Foundry for Ductile Iron Castings

A foundry specializing in ductile iron components for heavy machinery was struggling with inconsistent nodularity and occasional chunky graphite formations, particularly in larger castings. This affected the ductility and fatigue life of their products. After conducting trials with various carbon sources, they adopted Graphitized Petroleum Coke/Low Nitrogen Recarburiser with a customized particle size for their induction furnace. The ultra-low nitrogen content ensured optimal conditions for magnesium treatment and graphite spherulite formation. Post-implementation, they observed a 98% nodularity consistency across their product range, leading to a 10% improvement in tensile strength uniformity and a 7% reduction in casting rejects due to microstructure issues. The enhanced fluidity also reduced misruns, proving the economic viability of the higher-grade recarburiser.

Case Study 3: Global Ferroalloy Producer

A producer of specialized ferroalloys required extremely high purity carbon for their alloying process to meet stringent client specifications. Traditional carbon sources introduced unacceptable levels of sulfur and ash, necessitating additional refining steps that increased production costs and cycle times. By integrating Graphitized Petroleum Coke/Low Nitrogen Recarburiser into their process, they were able to achieve the required purity directly, eliminating a significant post-treatment step. This resulted in a 5% reduction in overall production time per batch and a notable decrease in energy consumption associated with refining, demonstrating GPC/LNR's value in high-purity, high-value material production.

These case examples underscore the value proposition of investing in premium Graphitized Petroleum Coke/Low Nitrogen Recarburiser. It's not just about adding carbon; it's about optimizing the entire metallurgical process, enhancing product quality, reducing operational costs, and ultimately securing a competitive edge in demanding markets.

Quality Assurance and Trustworthiness: Our Commitment

In the B2B sector, trustworthiness is built upon consistent quality, reliable service, and transparent operations. As a leading supplier of Graphitized Petroleum Coke/Low Nitrogen Recarburiser, our commitment to these principles is unwavering. We understand that our product is a foundational component of your manufacturing process, and its quality directly impacts your output and reputation.

Certifications and Compliance

Our manufacturing facilities operate under stringent international standards. We are proud to hold:

- ISO 9001:2015 Certification: Demonstrating a robust Quality Management System that covers all aspects of production, from raw material sourcing to final product delivery.

- ISO 14001:2015 Certification: Reflecting our dedication to environmental responsibility and sustainable manufacturing practices, minimizing our ecological footprint.

- Regular Third-Party Audits: Our processes and products are regularly audited by independent third-party organizations to ensure compliance with industry benchmarks and customer specifications.

Comprehensive Quality Control Protocol

Every batch of Graphitized Petroleum Coke/Low Nitrogen Recarburiser undergoes multi-stage quality checks. This includes:

- Raw Material Inspection: Ensuring only high-quality calcined petroleum coke enters the process.

- In-Process Monitoring: Continuous monitoring of temperature, pressure, and atmosphere during graphitization to ensure optimal transformation.

- Finished Product Analysis: Rigorous laboratory testing for fixed carbon, sulfur, nitrogen, ash, volatile matter, moisture, and particle size distribution. Each shipment is accompanied by a Certificate of Analysis (CoA).

- Batch Traceability: Full traceability from raw material to final packaged product, enabling quick identification and resolution of any issues.

Delivery Cycle and Supply Reliability

We understand the critical nature of 'just-in-time' inventory and consistent supply for our clients. Our robust logistics network and efficient production planning ensure reliable delivery cycles. Typical delivery times are quoted based on order volume and destination, with standard orders generally fulfilled within 2-4 weeks. We maintain strategic inventory levels to accommodate urgent requirements and minimize lead times for our long-term partners. Our commitment is to ensure your production lines never face disruption due to material shortages of Graphitized Petroleum Coke/Low Nitrogen Recarburiser.

Warranty and Customer Support

We stand behind the quality of our Graphitized Petroleum Coke/Low Nitrogen Recarburiser with a comprehensive product warranty, guaranteeing that our materials meet or exceed the specified technical parameters. Our dedicated customer support team and technical experts are available to provide:

- Pre-sales Consultation: Assisting with product selection and grade optimization for your specific application.

- Technical Guidance: Support for optimal addition methods, process integration, and troubleshooting.

- Post-sales Service: Prompt response to any queries or concerns regarding product performance or delivery.

Our long-standing relationships with global metallurgical enterprises are a testament to our reliability, quality, and customer-centric approach. Partnering with us means securing a consistent supply of premium Graphitized Petroleum Coke/Low Nitrogen Recarburiser backed by unparalleled expertise and support.

Frequently Asked Questions (FAQ) about Graphitized Petroleum Coke/Low Nitrogen Recarburiser

Q1: What is the primary difference between Graphitized Petroleum Coke and Calcined Petroleum Coke (CPC)?

Graphitized Petroleum Coke/Low Nitrogen Recarburiser undergoes an additional, intense high-temperature treatment (graphitization) at 2500-3000°C, transforming its amorphous carbon structure into a highly ordered, crystalline graphite structure. This process significantly reduces impurities like sulfur and nitrogen and enhances its reactivity and carbon recovery in molten metal. Calcined Petroleum Coke (CPC) is processed at lower temperatures (typically 1200-1400°C) primarily to remove volatile matter, making it less pure and reactive than GPC.

Q2: Why is "Low Nitrogen" important for recarburisers in steelmaking and foundries?

Nitrogen is an undesirable element in most ferrous alloys. In steel, excess nitrogen can cause porosity, pinholes, and lead to the formation of nitrides, which can reduce ductility and impact strength. In cast iron, particularly ductile iron, nitrogen can interfere with spheroidal graphite formation, leading to undesirable chunky graphite or pinholes. Using a Graphitized Petroleum Coke/Low Nitrogen Recarburiser minimizes these detrimental effects, ensuring superior mechanical properties and fewer casting defects.

Q3: How does the particle size of GPC/LNR affect its performance?

Particle size is crucial for optimal dissolution and carbon recovery. Finer particles (e.g., 0-1mm) dissolve rapidly and are often preferred for ladle additions or for achieving precise carbon adjustments. Coarser particles (e.g., 3-8mm) are typically used for furnace additions, offering controlled dissolution and minimizing loss. The correct particle size of Graphitized Petroleum Coke/Low Nitrogen Recarburiser ensures efficient absorption into the melt without excessive dusting or floating.

Q4: Can Graphitized Petroleum Coke/Low Nitrogen Recarburiser be customized?

Yes, leading manufacturers often offer customization options for Graphitized Petroleum Coke/Low Nitrogen Recarburiser. This includes tailored particle size distributions, specific packaging solutions (e.g., jumbo bags, smaller paper bags), and even minor adjustments to chemical specifications (e.g., even lower sulfur or ash content) based on specific client requirements and application needs.

Q5: What are the environmental benefits of using GPC/LNR compared to other recarburisers?

Due to its low volatile matter and low sulfur content, Graphitized Petroleum Coke/Low Nitrogen Recarburiser generates significantly less smoke and SOx emissions during addition compared to some traditional recarburisers like coal or ungraphitized coke. Its high efficiency also means less material needs to be consumed, reducing overall resource utilization and associated environmental impacts. This helps companies meet increasingly stringent environmental regulations.

Future Trends in Recarburiser Technology

The metallurgical industry is constantly evolving, driven by demands for higher performance, greater efficiency, and reduced environmental impact. This evolution directly influences the development of materials like Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Several key trends are shaping the future of recarburiser technology:

1. Increasing Demand for Ultra-High Purity

As advanced materials and specialty alloys become more prevalent, the tolerance for impurities in steel and cast iron diminishes. This will drive the demand for recarburisers with even lower levels of sulfur, nitrogen, and ash. Manufacturers of Graphitized Petroleum Coke/Low Nitrogen Recarburiser are already pushing the boundaries of purification technologies to meet these exacting requirements.

2. Enhanced Performance and Efficiency

Future developments will focus on improving the dissolution kinetics and carbon recovery efficiency of recarburisers. This might involve innovative surface treatments, novel particle shapes, or composite materials that facilitate even faster and more complete carbon absorption, further reducing energy consumption and process times in furnaces. The goal is to maximize the utility of every gram of Graphitized Petroleum Coke/Low Nitrogen Recarburiser added to the melt.

3. Sustainability and Circular Economy Principles

The industry is increasingly moving towards sustainable practices. This translates to a demand for recarburisers produced with reduced energy consumption, lower emissions, and potentially from recycled or bio-based feedstocks where feasible. While the production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is energy-intensive, research into more efficient graphitization processes and carbon capture technologies will be key.

4. Digitalization and Smart Manufacturing

Integration of recarburiser addition into smart manufacturing systems will become more common. This includes automated feeding systems, real-time analysis of melt chemistry, and AI-driven predictive models to optimize carbon additions. Suppliers of Graphitized Petroleum Coke/Low Nitrogen Recarburiser will need to ensure their products are compatible with these advanced systems, offering consistent physical properties for automated handling and precise chemical composition for algorithmic control.

These trends indicate a continued trajectory towards more specialized, highly purified, and intelligently applied recarburising agents. As the industry advances, the role of materials like Graphitized Petroleum Coke/Low Nitrogen Recarburiser, with its inherent advantages in purity and performance, will only grow in importance.

Conclusion: The Indispensable Role of Advanced Recarburisers

The dynamic landscape of modern metallurgy places ever-increasing demands on material purity, process efficiency, and product integrity. In this context, the role of high-performance recarburising agents cannot be overstated. Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands out as a superior solution, engineered to meet the stringent requirements of contemporary steelmaking and foundry operations.

From its meticulous manufacturing process, involving high-temperature graphitization and rigorous quality control, to its profound impact on melt chemistry and final product quality, GPC/LNR offers a compelling value proposition. Its low nitrogen, low sulfur, and high fixed carbon content directly translate into enhanced carbon recovery, reduced defects, improved mechanical properties, and significant operational savings. It is an investment that yields measurable returns in terms of efficiency, product reliability, and competitive advantage.

For B2B decision-makers and technical specialists seeking to optimize their metallurgical processes and produce superior ferrous alloys, the choice of a high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser is no longer merely an option but a strategic imperative. Partnering with a trusted manufacturer committed to continuous innovation, uncompromising quality, and exceptional customer support ensures a reliable supply chain and access to the technical expertise needed to thrive in today's demanding industrial environment. Embrace the future of metallurgical excellence with advanced recarburising solutions.

References

- Brooks, C.R. (2008). Heat Treatment, Structure and Properties of Nonferrous Alloys. ASM International.

- ASM International. (2001). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- Gündüz, M., & Yüksel, S. (2009). The effect of carbon source on microstructure and mechanical properties of grey cast iron. Materials & Design, 30(2), 244-249.

- Oates, J.A.H. (2008). Lime and Limestone: Chemistry and Technology, Production and Uses. Wiley-VCH.

- United States Environmental Protection Agency. (2004). AP 42, Fifth Edition, Volume I Chapter 12: Metallurgical Industry.

- Schulz, H., & Schulze, V. (2002). Effect of nitrogen in steel. Materials Science and Engineering: A, 329-331, 350-357.

- International Organization for Standardization (ISO). Various standards related to quality management and environmental management systems (ISO 9001, ISO 14001).

- American Society for Testing and Materials (ASTM). Various standards for carbon materials (e.g., ASTM D3172, ASTM D4239).

- Fukunaka, Y., & Oishi, T. (2014). Carbon materials for metallurgical applications. Journal of Japan Institute of Metals and Materials, 78(8), 296-302.

Navigating the Advanced World of High-Performance Recarburisers

In the demanding landscape of modern metallurgy, the quest for superior material purity and precise chemical control is paramount. Industries like steel manufacturing, foundries, and specialized alloy production are continuously seeking advanced solutions to optimize their processes, enhance product quality, and minimize environmental impact. Central to achieving these objectives is the selection of high-quality recarburising agents. Among the most advanced options available today is Graphitized Petroleum Coke/Low Nitrogen Recarburiser (GPC/LNR).

This sophisticated material represents a significant leap forward from conventional recarburisers, offering unparalleled purity, consistency, and performance. Its unique properties are derived from a meticulously controlled manufacturing process, transforming raw petroleum coke into a highly graphitized, low-nitrogen carbon source. This article delves deep into the technical intricacies, application benefits, and strategic considerations surrounding this critical metallurgical additive, providing B2B decision-makers and technical professionals with the insights needed to make informed choices for their operations.

We will explore the industry trends driving the demand for high-purity carbon, dissect the technical parameters that define superior GPC/LNR, illustrate its diverse application scenarios, highlight its distinct advantages over traditional alternatives, and offer guidance on selecting a reputable manufacturer. Furthermore, we will present compelling data, real-world application examples, and a robust framework for assessing trustworthiness, ensuring a comprehensive understanding of this indispensable material.

Understanding Graphitized Petroleum Coke/Low Nitrogen Recarburiser: A Technical Deep Dive

At its core, Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a carbonaceous material derived from petroleum coke, which undergoes intense thermal treatment at extremely high temperatures (typically above 2500°C) in a process known as graphitization. This process transforms the amorphous carbon structure of raw petroleum coke into a highly ordered, crystalline graphite structure, dramatically improving its purity, conductivity, and carbon recovery efficiency. The "Low Nitrogen" aspect signifies a further refinement to minimize nitrogen content, which is crucial for preventing nitrogen-related defects in steel and cast iron.

The superior performance of GPC/LNR stems from its unique properties:

- High Carbon Content (>98.5%): Ensures maximum carbon addition with minimal impurities.

- Low Sulfur Content ( Essential for preventing brittleness and other sulfur-induced defects in metals.

- Low Nitrogen Content ( Crucial for high-grade steels and cast irons where nitrogen can cause porosity, embrittlement, and reduced mechanical properties.

- High Graphitization Degree: Facilitates rapid dissolution and high carbon recovery in molten metal, enhancing efficiency.

- Consistent Particle Size Distribution: Critical for controlled carbon addition and preventing dusting or segregation during handling and use.

The transformation into a graphitized material leads to improved solubility in molten metals, making it an ideal choice for precise carbon adjustments in various melting processes, including electric arc furnaces (EAFs), induction furnaces, and cupola furnaces.

Key Technical Parameters of Graphitized Petroleum Coke/Low Nitrogen Recarburiser

Understanding the specific technical parameters is vital for selecting the appropriate grade of Graphitized Petroleum Coke/Low Nitrogen Recarburiser for a given metallurgical application. Below is a typical specification table:

| Parameter | Typical Value Range | Significance |

|---|---|---|

| Fixed Carbon (FC) | > 98.5% | Indicates the effective carbon content available for carburization. Higher FC means less material needed. |

| Sulfur (S) | < 0.05% | Lower sulfur reduces the risk of hot shortness, embrittlement, and environmental emissions. |

| Nitrogen (N) | < 100 ppm (0.01%) | Crucial for preventing porosity, blowholes, and nitrogen-related defects in precision castings and high-strength steels. |

| Ash Content | < 0.5% | Represents non-combustible impurities. Lower ash reduces slag formation and contamination of the melt. |

| Volatile Matter (VM) | < 0.5% | Indicates combustible gases released upon heating. Lower VM means less smoke, better recovery, and safer handling. |

| Moisture | < 0.5% | Minimizes hydrogen pick-up in the melt and prevents splashing during addition. |

| Particle Size | 0-1mm, 1-5mm, 3-8mm, 5-10mm, etc. (customizable) | Optimized for dissolution rate and application method (e.g., ladle addition, furnace addition). |

The Manufacturing Process: From Raw Material to High-Performance Recarburiser

The production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a complex, energy-intensive process that transforms raw petroleum coke into a highly purified and crystalline carbon product. Unlike the manufacturing of metal components through casting or forging, GPC/LNR production involves a series of high-temperature thermal treatments and meticulous material handling. The primary steps include:

- Raw Material Selection: High-quality calcined petroleum coke (CPC) with low sulfur and ash content is chosen as the primary feedstock. This initial selection is critical for the final product's purity.

- Crushing and Sizing: The CPC is crushed to a specific particle size distribution to ensure uniform processing in subsequent stages.

- Graphitization Furnace Loading: The prepared coke is loaded into specialized graphitization furnaces. These are typically Acheson furnaces or similar resistance-heating furnaces capable of reaching extremely high temperatures.

- High-Temperature Graphitization (2500°C - 3000°C): This is the most crucial step. The coke is heated under controlled atmospheric conditions (often inert gas) to temperatures ranging from 2500°C to 3000°C. At these extreme temperatures, the carbon atoms rearrange from an amorphous or turbostratic structure into a highly ordered, three-dimensional graphitic crystalline lattice. This process drives off residual impurities, including sulfur and nitrogen, and significantly improves electrical and thermal conductivity, and most importantly, reactivity in molten metal.

- Post-Processing: The cooled graphitized petroleum coke is then further crushed, screened, and classified into various particle size fractions according to customer specifications. Advanced screening and dedusting technologies ensure a consistent and clean product.

- Quality Control: Throughout the entire process, stringent quality control measures are implemented. This includes chemical analysis (fixed carbon, sulfur, nitrogen, ash, volatile matter, moisture), physical testing (particle size distribution, density), and morphological examination (graphitization degree).

Detection Standards and Quality Assurance

Adherence to international standards is paramount for ensuring the quality and consistency of Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Reputable manufacturers typically follow standards such as:

- ISO 9001: For Quality Management Systems, ensuring consistent production and customer satisfaction.

- ISO 14001: For Environmental Management Systems, reflecting a commitment to sustainable practices.

- Specific ASTM Standards: For testing and analysis of carbon materials, such as ASTM D3172 (Proximate Analysis), ASTM D4239 (Sulfur content), and specialized methods for nitrogen.

The rigorous manufacturing process, coupled with strict quality control and adherence to international standards, ensures that the resulting Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a high-purity, low-impurity material, optimized for superior carbon recovery and minimal detrimental effects on the molten metal. The typical service life of such a material is directly tied to its consumption rate in metallurgical processes, but its intrinsic quality ensures stable performance throughout its use in a melt.

Applications Across Industries: Where Purity Matters

The primary application of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is in the metallurgical industry, where it serves as a critical carbon additive. Its high purity and rapid dissolution make it indispensable for processes demanding precise carbon control and low impurity levels. While the prompt mentions petrochemical, metallurgy, and water supply/drainage, the core use of GPC/LNR is overwhelmingly in high-end metallurgical applications due to its specialized nature. We will focus on these key sectors:

1. Steelmaking Industry

In electric arc furnaces (EAFs) and induction furnaces, Graphitized Petroleum Coke/Low Nitrogen Recarburiser is used to increase the carbon content of molten steel to specified levels. Carbon is a vital alloying element that imparts strength, hardness, and other mechanical properties to steel. Its low nitrogen content is particularly critical in producing advanced high-strength steels (AHSS), specialty steels, and tool steels, where nitrogen can lead to:

- Nitrogen Porosity: Formation of gas bubbles, leading to defects and reduced mechanical integrity.

- Nitride Formation: Leading to embrittlement and reduced ductility.

- Surface Defects: Compromising the aesthetic and functional quality of the final product.

The high carbon recovery rate of GPC/LNR also contributes to energy efficiency by reducing the overall amount of additive required and shortening tap-to-tap times.

2. Foundry Industry (Cast Iron Production)

For cast iron production, whether grey iron, ductile iron, or malleable iron, controlled carbon content is essential for defining microstructures, fluidity, and mechanical properties. Graphitized Petroleum Coke/Low Nitrogen Recarburiser is preferred due to its ability to dissolve quickly and cleanly in the melt, promoting uniform carbon distribution and graphitization:

- Elimination of Carbides: Helps prevent the formation of hard, brittle carbides, which can lead to machining difficulties and reduced strength.

- Improved Fluidity: Optimized carbon levels contribute to better melt fluidity, crucial for casting intricate shapes.

- Reduced Shrinkage and Porosity: Proper carbon control, particularly with low nitrogen, minimizes casting defects.

- Consistent Microstructure: Leading to predictable mechanical properties and reduced scrap rates.

The "low nitrogen" aspect is especially beneficial in ductile iron production, where excess nitrogen can interfere with spheroidal graphite formation, leading to chunky graphite and reduced mechanical properties. By using Graphitized Petroleum Coke/Low Nitrogen Recarburiser, foundries can achieve superior nodularity and consistent ductile iron quality.

3. Special Alloys and Master Alloys

For producers of high-performance alloys where precise chemical composition is critical, GPC/LNR offers the necessary purity and controlled carbon input. This includes specialized ferroalloys and other master alloys where any impurity can drastically alter the final product's characteristics.

In all these applications, the advantages extend beyond mere carbon addition. The use of high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser translates directly into improved product consistency, reduced material consumption, lower energy costs, and ultimately, a more competitive final product in the market. While applications in petrochemicals or water treatment are typically associated with other forms of carbon (e.g., activated carbon for filtration), GPC/LNR's strength lies in its metallurgical efficacy, specifically where high carbon recovery and ultra-low nitrogen are non-negotiable.

Technical Advantages and Performance Metrics

The distinct advantages of utilizing Graphitized Petroleum Coke/Low Nitrogen Recarburiser over alternative carbon sources are profound, directly impacting operational efficiency, product quality, and cost-effectiveness. These advantages are rooted in its unique structural and chemical properties:

1. Superior Carbon Recovery and Efficiency

Due to its high graphitization degree, GPC/LNR exhibits exceptional solubility and dissolution rates in molten metal. This leads to very high carbon recovery rates, often exceeding 95%. In contrast, less graphitized or amorphous carbon sources may have lower recovery, meaning more material is required to achieve the target carbon content, leading to higher consumption costs and increased slag volume. The rapid dissolution minimizes the time the furnace is open, contributing to energy savings and increased productivity (e.g., shorter tap-to-tap times in EAFs).

2. Precisely Controlled Low Nitrogen Content

The "Low Nitrogen" aspect is a critical differentiator. Nitrogen is a detrimental element in many ferrous alloys, leading to defects such as pinholes, porosity, and embrittlement. Traditional recarburisers like metallurgical coke or even ungraphitized petroleum coke can introduce significant levels of nitrogen (hundreds to thousands of ppm). By rigorously controlling nitrogen levels to below 100 ppm, Graphitized Petroleum Coke/Low Nitrogen Recarburiser prevents these issues, ensuring the integrity and mechanical properties of high-grade steels and precision castings. This is particularly vital for safety-critical components in automotive, aerospace, and energy sectors.

3. Minimal Impurities (Sulfur, Ash, Volatile Matter)

The intensive graphitization process effectively removes most of the undesirable impurities present in raw petroleum coke. The resultant low sulfur content (

4. Enhanced Melt Quality and Reduced Defects

The combination of high carbon purity, low nitrogen, and rapid dissolution directly translates into improved melt quality. It helps in achieving a more homogeneous carbon distribution within the molten metal, which is fundamental for consistent microstructure development upon solidification. This consistency reduces the likelihood of casting defects such as porosity, shrinkage, hard spots, and internal stresses, leading to fewer rejected parts and higher yields.

By using Graphitized Petroleum Coke/Low Nitrogen Recarburiser, manufacturers can:

- Optimize Production Costs: Through higher carbon recovery, reduced material consumption, and lower energy expenditure.

- Improve Product Performance: Achieve desired mechanical properties and microstructure without detrimental impurities.

- Reduce Environmental Footprint: Lower emissions and less slag generation.

- Increase Operational Stability: Predictable performance leads to fewer process adjustments and reduced downtime.

These performance metrics underscore why investing in high-grade Graphitized Petroleum Coke/Low Nitrogen Recarburiser is not merely an expense, but a strategic decision that drives long-term profitability and competitiveness in the metallurgy sector.

Choosing the Right Supplier: Manufacturer Comparison & Custom Solutions

Selecting the right supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser is as critical as understanding the product itself. The market offers various grades and qualities, and aligning with a reputable manufacturer can significantly impact your production efficiency, product quality, and supply chain reliability. Here are key factors to consider when evaluating potential partners:

1. Manufacturing Expertise and Technology

A leading manufacturer will possess state-of-the-art graphitization furnaces and advanced processing equipment. Inquire about their production capacity, process control systems, and R&D capabilities. Companies that continuously invest in technological upgrades are more likely to deliver consistent, high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Look for evidence of extensive experience in carbon material science and a deep understanding of metallurgical processes.

2. Stringent Quality Control and Certifications

Verify the supplier's quality assurance protocols. Do they have an ISO 9001 certified Quality Management System? Are their products regularly tested against international standards (e.g., ASTM)? Request recent Certificates of Analysis (CoAs) for their Graphitized Petroleum Coke/Low Nitrogen Recarburiser batches. A transparent manufacturer will readily provide documentation demonstrating their commitment to purity, consistency, and traceability.

3. Customization Capabilities

Metallurgical processes vary significantly, requiring different particle sizes, packaging, and sometimes even nuanced chemical compositions. A flexible supplier should be able to offer customized solutions for Graphitized Petroleum Coke/Low Nitrogen Recarburiser. This includes tailoring particle size distribution (e.g., 0-1mm for ladle additions, 3-8mm for furnace additions), packaging options (bulk bags, paper bags), and even specific impurity limits if required by niche applications. This adaptability can optimize your material handling and furnace integration.

4. Supply Chain Reliability and Logistics

Timely and reliable delivery is crucial for uninterrupted production. Assess the supplier's logistical capabilities, global reach, and inventory management. A strong supplier will have robust supply chain management to ensure consistent availability of Graphitized Petroleum Coke/Low Nitrogen Recarburiser and on-time delivery, minimizing costly downtime for your operations. Inquire about their typical delivery cycles and their ability to handle emergency orders.

5. Technical Support and Customer Service

Beyond product delivery, a valuable partner offers technical support. This might include assistance with product selection, optimization of addition methods, troubleshooting, and post-sales service. Companies with dedicated technical teams demonstrate a commitment to customer success and foster long-term partnerships. Check for customer testimonials and case studies that highlight their service excellence.

By systematically evaluating these aspects, B2B buyers can identify a supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser that not only meets their immediate product needs but also acts as a strategic partner, contributing to process optimization and overall business growth.

Application Cases and Success Stories

The real-world impact of high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser is best demonstrated through its successful application in various metallurgical operations. While specific client names are confidential, we can illustrate typical scenarios where its adoption has yielded significant benefits:

Case Study 1: High-Strength Steel Manufacturer

A major steel producer, focused on automotive and structural steels, faced recurring issues with nitrogen porosity in their ladle furnace operations. Despite meticulous control of other additives, high nitrogen levels persisted, leading to increased rejection rates and costly rework. Upon switching from a traditional recarburiser to a premium grade of Graphitized Petroleum Coke/Low Nitrogen Recarburiser, the immediate impact was a dramatic reduction in nitrogen pick-up in the molten steel. Within three months, their scrap rate due to nitrogen porosity dropped by 15%, and the consistency of mechanical properties improved significantly. This translated into substantial cost savings and enhanced reputation for quality.

Case Study 2: Precision Foundry for Ductile Iron Castings

A foundry specializing in ductile iron components for heavy machinery was struggling with inconsistent nodularity and occasional chunky graphite formations, particularly in larger castings. This affected the ductility and fatigue life of their products. After conducting trials with various carbon sources, they adopted Graphitized Petroleum Coke/Low Nitrogen Recarburiser with a customized particle size for their induction furnace. The ultra-low nitrogen content ensured optimal conditions for magnesium treatment and graphite spherulite formation. Post-implementation, they observed a 98% nodularity consistency across their product range, leading to a 10% improvement in tensile strength uniformity and a 7% reduction in casting rejects due to microstructure issues. The enhanced fluidity also reduced misruns, proving the economic viability of the higher-grade recarburiser.

Case Study 3: Global Ferroalloy Producer

A producer of specialized ferroalloys required extremely high purity carbon for their alloying process to meet stringent client specifications. Traditional carbon sources introduced unacceptable levels of sulfur and ash, necessitating additional refining steps that increased production costs and cycle times. By integrating Graphitized Petroleum Coke/Low Nitrogen Recarburiser into their process, they were able to achieve the required purity directly, eliminating a significant post-treatment step. This resulted in a 5% reduction in overall production time per batch and a notable decrease in energy consumption associated with refining, demonstrating GPC/LNR's value in high-purity, high-value material production.

These case examples underscore the value proposition of investing in premium Graphitized Petroleum Coke/Low Nitrogen Recarburiser. It's not just about adding carbon; it's about optimizing the entire metallurgical process, enhancing product quality, reducing operational costs, and ultimately securing a competitive edge in demanding markets.

Quality Assurance and Trustworthiness: Our Commitment

In the B2B sector, trustworthiness is built upon consistent quality, reliable service, and transparent operations. As a leading supplier of Graphitized Petroleum Coke/Low Nitrogen Recarburiser, our commitment to these principles is unwavering. We understand that our product is a foundational component of your manufacturing process, and its quality directly impacts your output and reputation.

Certifications and Compliance

Our manufacturing facilities operate under stringent international standards. We are proud to hold:

- ISO 9001:2015 Certification: Demonstrating a robust Quality Management System that covers all aspects of production, from raw material sourcing to final product delivery.

- ISO 14001:2015 Certification: Reflecting our dedication to environmental responsibility and sustainable manufacturing practices, minimizing our ecological footprint.

- Regular Third-Party Audits: Our processes and products are regularly audited by independent third-party organizations to ensure compliance with industry benchmarks and customer specifications.

Comprehensive Quality Control Protocol

Every batch of Graphitized Petroleum Coke/Low Nitrogen Recarburiser undergoes multi-stage quality checks. This includes:

- Raw Material Inspection: Ensuring only high-quality calcined petroleum coke enters the process.

- In-Process Monitoring: Continuous monitoring of temperature, pressure, and atmosphere during graphitization to ensure optimal transformation.

- Finished Product Analysis: Rigorous laboratory testing for fixed carbon, sulfur, nitrogen, ash, volatile matter, moisture, and particle size distribution. Each shipment is accompanied by a Certificate of Analysis (CoA).

- Batch Traceability: Full traceability from raw material to final packaged product, enabling quick identification and resolution of any issues.

Delivery Cycle and Supply Reliability

We understand the critical nature of 'just-in-time' inventory and consistent supply for our clients. Our robust logistics network and efficient production planning ensure reliable delivery cycles. Typical delivery times are quoted based on order volume and destination, with standard orders generally fulfilled within 2-4 weeks. We maintain strategic inventory levels to accommodate urgent requirements and minimize lead times for our long-term partners. Our commitment is to ensure your production lines never face disruption due to material shortages of Graphitized Petroleum Coke/Low Nitrogen Recarburiser.

Warranty and Customer Support

We stand behind the quality of our Graphitized Petroleum Coke/Low Nitrogen Recarburiser with a comprehensive product warranty, guaranteeing that our materials meet or exceed the specified technical parameters. Our dedicated customer support team and technical experts are available to provide:

- Pre-sales Consultation: Assisting with product selection and grade optimization for your specific application.

- Technical Guidance: Support for optimal addition methods, process integration, and troubleshooting.

- Post-sales Service: Prompt response to any queries or concerns regarding product performance or delivery.

Our long-standing relationships with global metallurgical enterprises are a testament to our reliability, quality, and customer-centric approach. Partnering with us means securing a consistent supply of premium Graphitized Petroleum Coke/Low Nitrogen Recarburiser backed by unparalleled expertise and support.

Frequently Asked Questions (FAQ) about Graphitized Petroleum Coke/Low Nitrogen Recarburiser

Q1: What is the primary difference between Graphitized Petroleum Coke and Calcined Petroleum Coke (CPC)?

Graphitized Petroleum Coke/Low Nitrogen Recarburiser undergoes an additional, intense high-temperature treatment (graphitization) at 2500-3000°C, transforming its amorphous carbon structure into a highly ordered, crystalline graphite structure. This process significantly reduces impurities like sulfur and nitrogen and enhances its reactivity and carbon recovery in molten metal. Calcined Petroleum Coke (CPC) is processed at lower temperatures (typically 1200-1400°C) primarily to remove volatile matter, making it less pure and reactive than GPC.

Q2: Why is "Low Nitrogen" important for recarburisers in steelmaking and foundries?

Nitrogen is an undesirable element in most ferrous alloys. In steel, excess nitrogen can cause porosity, pinholes, and lead to the formation of nitrides, which can reduce ductility and impact strength. In cast iron, particularly ductile iron, nitrogen can interfere with spheroidal graphite formation, leading to undesirable chunky graphite or pinholes. Using a Graphitized Petroleum Coke/Low Nitrogen Recarburiser minimizes these detrimental effects, ensuring superior mechanical properties and fewer casting defects.

Q3: How does the particle size of GPC/LNR affect its performance?

Particle size is crucial for optimal dissolution and carbon recovery. Finer particles (e.g., 0-1mm) dissolve rapidly and are often preferred for ladle additions or for achieving precise carbon adjustments. Coarser particles (e.g., 3-8mm) are typically used for furnace additions, offering controlled dissolution and minimizing loss. The correct particle size of Graphitized Petroleum Coke/Low Nitrogen Recarburiser ensures efficient absorption into the melt without excessive dusting or floating.

Q4: Can Graphitized Petroleum Coke/Low Nitrogen Recarburiser be customized?

Yes, leading manufacturers often offer customization options for Graphitized Petroleum Coke/Low Nitrogen Recarburiser. This includes tailored particle size distributions, specific packaging solutions (e.g., jumbo bags, smaller paper bags), and even minor adjustments to chemical specifications (e.g., even lower sulfur or ash content) based on specific client requirements and application needs.

Q5: What are the environmental benefits of using GPC/LNR compared to other recarburisers?

Due to its low volatile matter and low sulfur content, Graphitized Petroleum Coke/Low Nitrogen Recarburiser generates significantly less smoke and SOx emissions during addition compared to some traditional recarburisers like coal or ungraphitized coke. Its high efficiency also means less material needs to be consumed, reducing overall resource utilization and associated environmental impacts. This helps companies meet increasingly stringent environmental regulations.

Future Trends in Recarburiser Technology

The metallurgical industry is constantly evolving, driven by demands for higher performance, greater efficiency, and reduced environmental impact. This evolution directly influences the development of materials like Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Several key trends are shaping the future of recarburiser technology:

1. Increasing Demand for Ultra-High Purity

As advanced materials and specialty alloys become more prevalent, the tolerance for impurities in steel and cast iron diminishes. This will drive the demand for recarburisers with even lower levels of sulfur, nitrogen, and ash. Manufacturers of Graphitized Petroleum Coke/Low Nitrogen Recarburiser are already pushing the boundaries of purification technologies to meet these exacting requirements.

2. Enhanced Performance and Efficiency

Future developments will focus on improving the dissolution kinetics and carbon recovery efficiency of recarburisers. This might involve innovative surface treatments, novel particle shapes, or composite materials that facilitate even faster and more complete carbon absorption, further reducing energy consumption and process times in furnaces. The goal is to maximize the utility of every gram of Graphitized Petroleum Coke/Low Nitrogen Recarburiser added to the melt.

3. Sustainability and Circular Economy Principles

The industry is increasingly moving towards sustainable practices. This translates to a demand for recarburisers produced with reduced energy consumption, lower emissions, and potentially from recycled or bio-based feedstocks where feasible. While the production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is energy-intensive, research into more efficient graphitization processes and carbon capture technologies will be key.

4. Digitalization and Smart Manufacturing

Integration of recarburiser addition into smart manufacturing systems will become more common. This includes automated feeding systems, real-time analysis of melt chemistry, and AI-driven predictive models to optimize carbon additions. Suppliers of Graphitized Petroleum Coke/Low Nitrogen Recarburiser will need to ensure their products are compatible with these advanced systems, offering consistent physical properties for automated handling and precise chemical composition for algorithmic control.

These trends indicate a continued trajectory towards more specialized, highly purified, and intelligently applied recarburising agents. As the industry advances, the role of materials like Graphitized Petroleum Coke/Low Nitrogen Recarburiser, with its inherent advantages in purity and performance, will only grow in importance.

Conclusion: The Indispensable Role of Advanced Recarburisers

The dynamic landscape of modern metallurgy places ever-increasing demands on material purity, process efficiency, and product integrity. In this context, the role of high-performance recarburising agents cannot be overstated. Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands out as a superior solution, engineered to meet the stringent requirements of contemporary steelmaking and foundry operations.

From its meticulous manufacturing process, involving high-temperature graphitization and rigorous quality control, to its profound impact on melt chemistry and final product quality, GPC/LNR offers a compelling value proposition. Its low nitrogen, low sulfur, and high fixed carbon content directly translate into enhanced carbon recovery, reduced defects, improved mechanical properties, and significant operational savings. It is an investment that yields measurable returns in terms of efficiency, product reliability, and competitive advantage.

For B2B decision-makers and technical specialists seeking to optimize their metallurgical processes and produce superior ferrous alloys, the choice of a high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser is no longer merely an option but a strategic imperative. Partnering with a trusted manufacturer committed to continuous innovation, uncompromising quality, and exceptional customer support ensures a reliable supply chain and access to the technical expertise needed to thrive in today's demanding industrial environment. Embrace the future of metallurgical excellence with advanced recarburising solutions.

References

- Brooks, C.R. (2008). Heat Treatment, Structure and Properties of Nonferrous Alloys. ASM International.

- ASM International. (2001). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- Gündüz, M., & Yüksel, S. (2009). The effect of carbon source on microstructure and mechanical properties of grey cast iron. Materials & Design, 30(2), 244-249.

- Oates, J.A.H. (2008). Lime and Limestone: Chemistry and Technology, Production and Uses. Wiley-VCH.

- United States Environmental Protection Agency. (2004). AP 42, Fifth Edition, Volume I Chapter 12: Metallurgical Industry.

- Schulz, H., & Schulze, V. (2002). Effect of nitrogen in steel. Materials Science and Engineering: A, 329-331, 350-357.

- International Organization for Standardization (ISO). Various standards related to quality management and environmental management systems (ISO 9001, ISO 14001).

- American Society for Testing and Materials (ASTM). Various standards for carbon materials (e.g., ASTM D3172, ASTM D4239).

- Fukunaka, Y., & Oishi, T. (2014). Carbon materials for metallurgical applications. Journal of Japan Institute of Metals and Materials, 78(8), 296-302.

This is the last article

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025