Jan . 20, 2025 09:55 Back to list

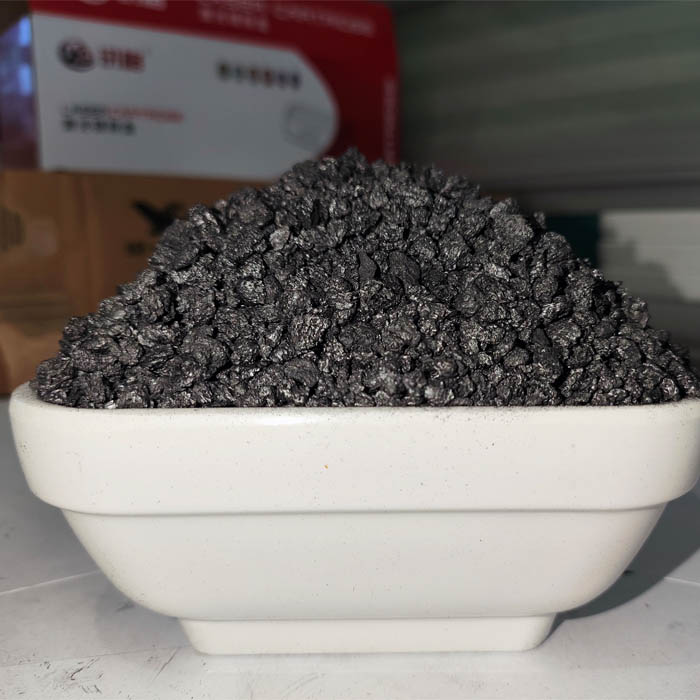

carbon petroleum coke exporters

EAF steel making has emerged as a revolutionary process in the steel manufacturing industry, offering numerous advantages over traditional blast furnace methods and aligning perfectly with contemporary environmental and efficiency demands. Drawing from years of professional experience and deep industry expertise, let's delve into the significant benefits and facets of Electric Arc Furnace (EAF) steel making that make it a preferred choice for modern-day steel production.

Establishing a trustworthy supply chain is paramount in the steel industry, and EAF steel making plays a critical role in this aspect. By relying on scrap steel, EAF ensures a steady and sustainable supply of raw materials, mitigating the risks associated with raw material scarcity and price volatility. This reliability enhances customer trust and secures long-term partnerships with stakeholders seeking dependable and reliable sources of steel. As the demand for greener and more efficient industrial processes intensifies, the role of EAF steel making becomes increasingly crucial. It aligns with global trends towards sustainable development and energy conservation, reinforcing its position as a leading choice for the environmentally-conscious manufacturer. For businesses considering the transition to EAF steel making, the benefits extend beyond environmental and operational advantages. The adaptability of the EAF process allows for the production of a wide range of steel grades, suitable for various applications from construction to automotive manufacturing. This versatility ensures that manufacturers can meet diverse customer needs and open new market opportunities, further supporting business growth and competitiveness. In conclusion, EAF steel making embodies the intersection of technological innovation, environmental sustainability, and operational excellence. Its ability to address contemporary challenges while offering significant economic and ecological benefits positions it as the future of steel manufacturing. Globally recognized and adopted by leading steel producers, EAF's authority and expertise in the industry are undeniable, paving the way for a more sustainable and resilient future in steel production. The trust it builds within the industry, combined with its proven track record of success, underscores its indispensable role in the modern industrial landscape.

Establishing a trustworthy supply chain is paramount in the steel industry, and EAF steel making plays a critical role in this aspect. By relying on scrap steel, EAF ensures a steady and sustainable supply of raw materials, mitigating the risks associated with raw material scarcity and price volatility. This reliability enhances customer trust and secures long-term partnerships with stakeholders seeking dependable and reliable sources of steel. As the demand for greener and more efficient industrial processes intensifies, the role of EAF steel making becomes increasingly crucial. It aligns with global trends towards sustainable development and energy conservation, reinforcing its position as a leading choice for the environmentally-conscious manufacturer. For businesses considering the transition to EAF steel making, the benefits extend beyond environmental and operational advantages. The adaptability of the EAF process allows for the production of a wide range of steel grades, suitable for various applications from construction to automotive manufacturing. This versatility ensures that manufacturers can meet diverse customer needs and open new market opportunities, further supporting business growth and competitiveness. In conclusion, EAF steel making embodies the intersection of technological innovation, environmental sustainability, and operational excellence. Its ability to address contemporary challenges while offering significant economic and ecological benefits positions it as the future of steel manufacturing. Globally recognized and adopted by leading steel producers, EAF's authority and expertise in the industry are undeniable, paving the way for a more sustainable and resilient future in steel production. The trust it builds within the industry, combined with its proven track record of success, underscores its indispensable role in the modern industrial landscape.

Latest news

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025