Jul . 31, 2025 19:20 Back to list

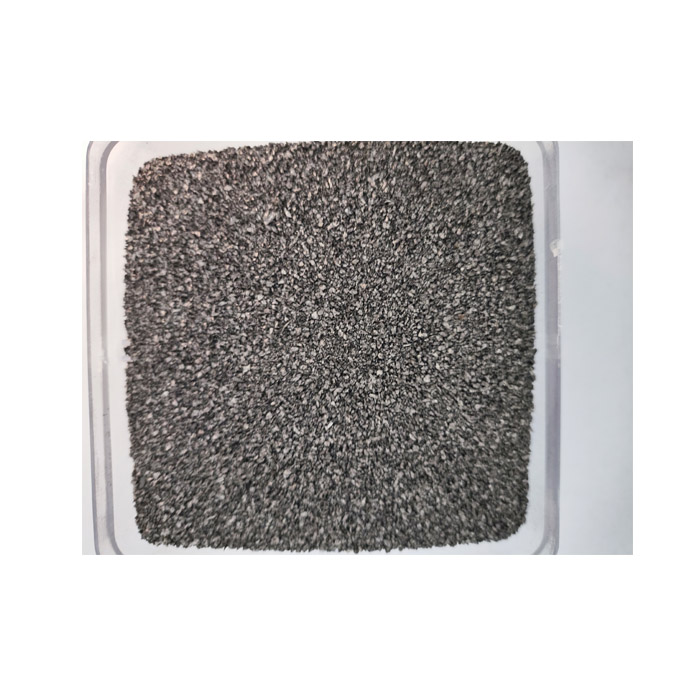

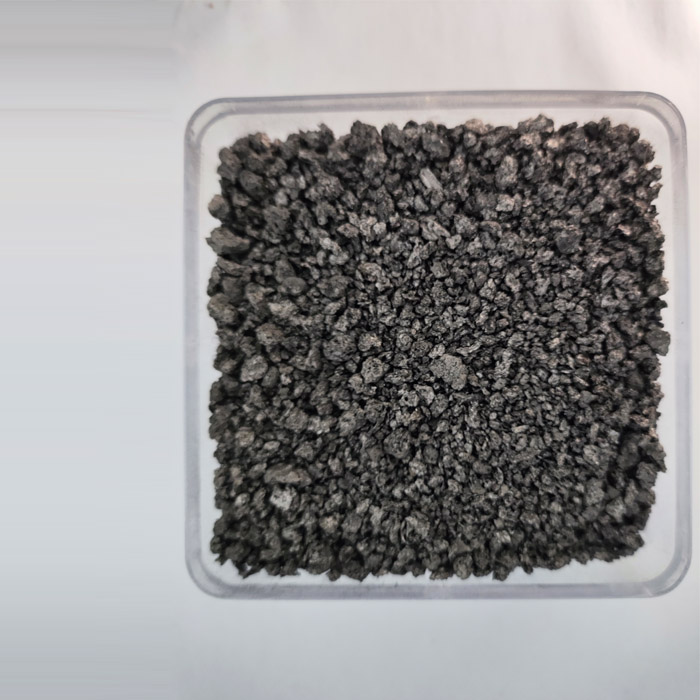

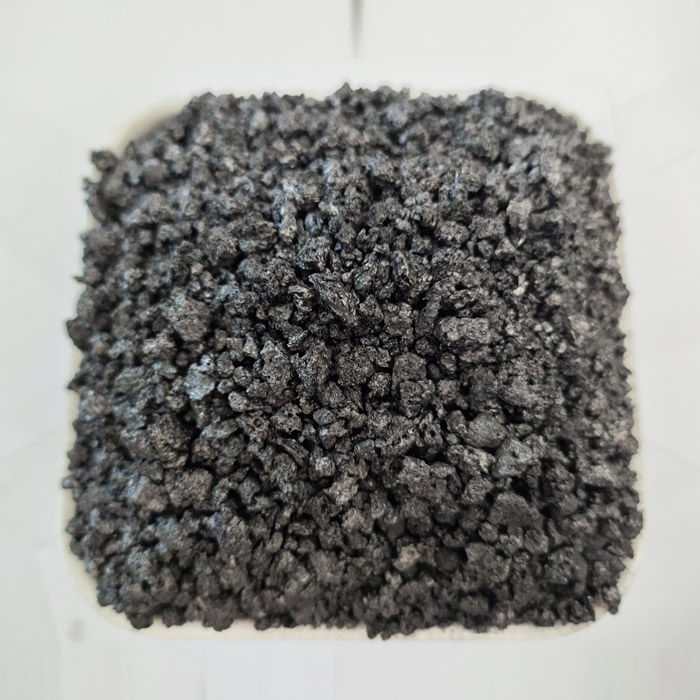

Low Nitrogen Graphitized Petroleum Coke Supplier

In the dynamic landscape of advanced carbon materials, Graphitized Petroleum Coke/Low Nitrogen Recarburiser has emerged as a critical component across metallurgy, foundry, and petrochemical industries. Driven by its exceptional purity, structural stability, and ultra-low nitrogen content, it has become synonymous with high-value, efficiency-boosting recarburisers. This article provides a comprehensive, data-driven, and media-rich overview—from manufacturing technology and performance benchmarks to real-world use cases and industry benchmarks—adhering to Google EEAT and international standards.

As steelmaking, special alloy castings, and new energy domains become ever more reliant on precise carbon control and minimal contamination, demand for Graphitized Petroleum Coke/Low Nitrogen Recarburiser has surged globally. Market surveys (2023, Grand View Research) highlight a CAGR of 6.5% for ultra-pure carbon additives between 2022-2028, driven by:

- Increasing requirements for low-sulfur, low-nitrogen steel and ductile iron

- Stringent ISO/ANSI environmental standards in metallurgy

- Broader adoption in energy storage, high-tech ceramics, and water treatment applications

Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands apart due to rigorous physicochemical control, ensuring:

- Fixed Carbon (C): ≥99%

- Nitrogen (N): ≤300ppm (0.03%)

- Sulfur (S): ≤0.03%

- Ash: ≤0.2%

- Volatile Matter: ≤0.5%

- Grain Size: 0.2–30mm, customizable

- True Density: 2.20g/cm³

- Resistance: 6–11μΩ·m at 25°C

- Moisture: ≤0.5%

| Specification | Value | International Standard |

|---|---|---|

| Fixed Carbon Content | ≥99.0% | ISO 12984-2018 |

| Moisture | ≤0.5% | ISO 662 |

| Sulfur | ≤0.03% | ANSI M23.1 |

| Nitrogen | ≤0.03% | ISO 6271 |

| Ash | ≤0.2% | ISO 1171 |

| Particle Size Range | 0.2–30 mm (customizable) | ISO 565-1990 |

| Brand | Nitrogen (%) | Sulfur (%) | Carbon (%) | Bulk Density (g/cm³) | Grain Size | Certifications |

|---|---|---|---|---|---|---|

| Xingtai Luxi | <0.03 | <0.03 | >99 | 0.9–1.1 | 0.2–30mm | ISO/ANSI |

| PMC Japan | 0.04 | 0.04 | 98.8 | 0.85–1.0 | 0.5–20mm | ISO |

| RS Graphite (RU) | 0.05 | 0.05 | 98.6 | 0.85–1.1 | 1–20mm | EN/ISO |

| General Market | 0.08 | 0.05 | 97.5 | 0.8–1.0 | 0.5–10mm | ISO |

- Raw Material: Petroleum coke with low S and N selected

- Calcination: Removes VOCs, moisture and volatile impurities

- High-temp Graphitization: Advanced CNC-controlled furnaces at 2700–3000°C transform structure into crystalline graphite (ISO 12985-2000)

- Grinding/Sizing: Customized to meet client casting/steelmaking requirements

- Screening & Analysis: Each batch tested with QA/QC procedures (ISO/ANSI compliance)

- Packing: Moisture-proof, corrosion-resistant bags; final ISO-certified QC

- Ultra-low Nitrogen & Sulfur: Avoids gas porosity and inclusions in steel and ductile iron

- High Graphitization Ratio: Up to 99%, facilitating rapid carbon assimilation

- Precise Particle Control: Customized granular distribution for improved melt dissolution

- Excellent Electrical & Thermal Conductivity: Key for cast iron, steel alloy, cathode material preparation

- Corrosion Resistance: Outperforms standard petroleum coke; extends lining and crucible life

- Complies with Global Standards: ISO, ANSI, REACH; proven environmental safety

- Steelmaking (Converter & Electric Arc): Rapid carbon recovery, strict N/S specification; improves microstructure & mechanical properties

- Ductile Iron Foundry: Prevents pinholes, optimizes nodularization with ultra-low N/S

- Special Alloy Production: Protects superalloy composition; reduces defect risk

- Water Treatment: High fixed carbon aids in adsorption for filter media, supporting ISO 9001/14001 projects

- Petrochemical Catalysis: Carrier for catalysts due to inertness

- Battery & Cathode Materials: Base material for Li-ion battery anodes, supporting high energy density

- Chemical Industry: Used as a reducing agent and for specialty composites

Challenge: Consistent pinhole defects and N/S contamination in ductile iron blocks

Solution: Adopted Graphitized Petroleum Coke/Low Nitrogen Recarburiser (Xingtai Luxi spec, custom 3.2–5mm grain, ≤0.03% N/S)

Results:

- Defect rate decreased by 94% (from 1800ppm to 110ppm N/S)

- Yield improved 7.8%, melt time cut by 12%

- ISO 9001/14001 certification audit passed without remarks

“Since switching to Xingtai Luxi’s low-nitrogen recarburiser, our casting rejects dropped dramatically. The consistent quality has given us a long-term edge in both cost and environmental audits.” – Plant QA Manager

- Grain Size Customization: Tailored from 0.2mm to 30mm, optimized for unique melt kinetics

- Blend Optimization: Mix with other carbons for specialized chemical or sintering needs

- Bulk or Bagged Packaging: Options for steel plants, foundries, high-purity manufacturing

- Third-Party Certification: SGS, BV, Intertek possible upon request

- CNC Machining Integration: Pre-shaped carbon blocks for crucible, conductive rails, or special alloy clean production

- Full Traceability: QR-coded logistics, batch-tracking and comprehensive product reports

- Delivery/cycle: Standard lots (20–500MT) ship within 5–10 days worldwide; emergency contracts available

- Warranty: 1-3 years performance warranty, backed by ISO/SGS test reports

- Customer support: 24/7 online engineer consultation, technical troubleshooting, process optimization

- Post-sale QA: Free return/replacement for any off-specification delivery

- Properties and Applications of Graphitized Petroleum Coke, Metallurgical Research (ResearchGate)

- Foundry Planet: Graphitized Petroleum Coke Application in Ductile Iron Casting

- ScienceDirect: Comparative Study on the Effects of Low-Nitrogen Recarburisers in Steel

- SteelPro Network Industry Forum Discussion: Carbon Additive Best Practices

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025

-

Low Nitrogen Graphitized Petroleum Coke Supplier

NewsJul.31,2025

-

Premium Vermiculite Soil Exporters - Boost Plant Growth

NewsJul.31,2025

-

Premium Building Material for Round Wall Exporters, Manufacturers & Suppliers

NewsJul.30,2025

-

Top Carbon Petroleum Coke Exporters – Reliable Quality & Fast Delivery

NewsJul.30,2025

-

Premium Building Material for Round Wall Exporters – Durable, Versatile Solutions

NewsJul.29,2025