Feb . 14, 2025 18:46 Back to list

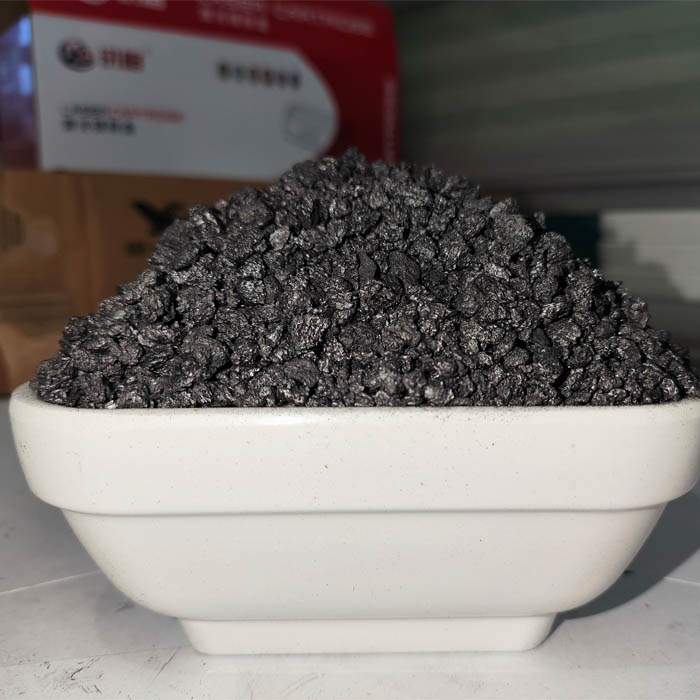

Tundish Dry Vibration Material

When selecting outdoor pipe insulation material, understanding the factors that influence performance and longevity in various climates is crucial. Not all insulation materials are created equal, and their effectiveness can vastly differ depending on the environmental conditions they face. This comprehensive guide delves into the critical factors that define the quality and applicability of outdoor pipe insulation materials.

Trust plays a substantial role in the selection of insulation materials. Choosing products from manufacturers with a robust track record for quality and compliance with industry standards is paramount. Products certified by recognized organizations for environmental and health safety bolster trustworthiness, as they meet rigorous testing and quality assurance standards. Professional installation further augments the efficacy of the chosen insulation material. Misapplication or poor handling can negate the benefits of even the highest quality materials. A skilled installer ensures that the seams are secure, the jackets are properly aligned, and that any penetrations through the insulation for hangers or supports are adequately sealed. In sustainability-conscious markets, low-impact environmental materials are gaining traction. Insulation products with recycled content or bio-based origins present an eco-friendly alternative without compromising performance. Additionally, selecting materials with low Global Warming Potential (GWP) and free of ozone-depleting substances contributes positively to the environment while adhering to modern regulatory demands. Regular maintenance and inspections are crucial for extending the life of outdoor pipe insulation. This involves checking for signs of wear, such as cracks, tears, or sections where insulation has been compromised, allowing timely repairs that prevent larger issues down the line. Choosing the appropriate outdoor pipe insulation material involves balancing several factors, including climate conditions, material properties, installation quality, and manufacturing credibility. By considering these factors, consumers can ensure the longevity, efficiency, and reliability of their insulation solutions, safeguarding their piping systems and contributing to broader energy conservation efforts.

Trust plays a substantial role in the selection of insulation materials. Choosing products from manufacturers with a robust track record for quality and compliance with industry standards is paramount. Products certified by recognized organizations for environmental and health safety bolster trustworthiness, as they meet rigorous testing and quality assurance standards. Professional installation further augments the efficacy of the chosen insulation material. Misapplication or poor handling can negate the benefits of even the highest quality materials. A skilled installer ensures that the seams are secure, the jackets are properly aligned, and that any penetrations through the insulation for hangers or supports are adequately sealed. In sustainability-conscious markets, low-impact environmental materials are gaining traction. Insulation products with recycled content or bio-based origins present an eco-friendly alternative without compromising performance. Additionally, selecting materials with low Global Warming Potential (GWP) and free of ozone-depleting substances contributes positively to the environment while adhering to modern regulatory demands. Regular maintenance and inspections are crucial for extending the life of outdoor pipe insulation. This involves checking for signs of wear, such as cracks, tears, or sections where insulation has been compromised, allowing timely repairs that prevent larger issues down the line. Choosing the appropriate outdoor pipe insulation material involves balancing several factors, including climate conditions, material properties, installation quality, and manufacturing credibility. By considering these factors, consumers can ensure the longevity, efficiency, and reliability of their insulation solutions, safeguarding their piping systems and contributing to broader energy conservation efforts.

Latest news

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025