மே . 07, 2025 19:43 Back to list

High-Strength Tire Cord Steel Trusted Suppliers & Exporters

- Industry Overview: Growth Trends in Reinforcement Materials

- Mechanical Superiority of High-Carbon Steel Alloys

- Performance Benchmark: Leading Suppliers Analysis

- Custom Metallurgical Solutions for Tire Cord Fabrication

- Global Export Networks and Logistics Efficiency

- Case Study: OEM Partnership in Commercial Truck Tires

- Sustainable Practices in Tire Cord Steel Manufacturing

(tire cord steel)

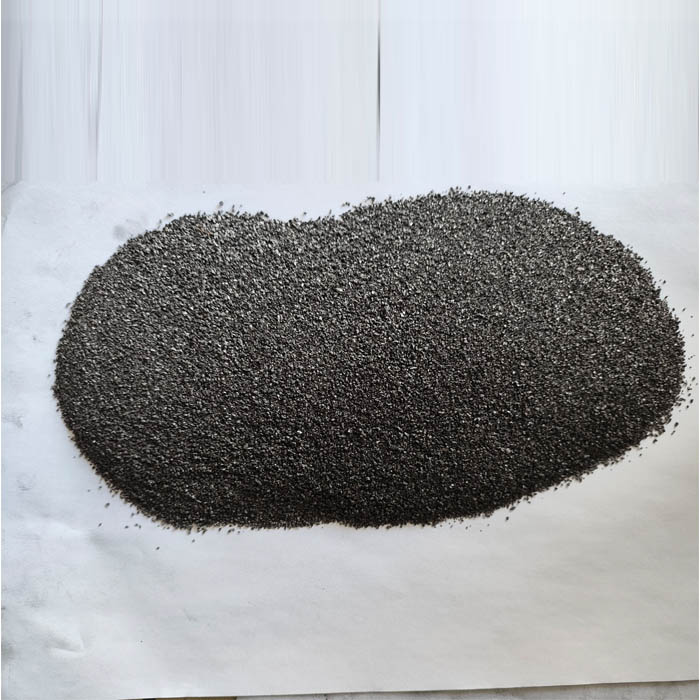

Tire Cord Steel: Powering Modern Mobility Infrastructure

The global tire cord steel

market reached $4.72 billion in 2023, driven by 6.8% CAGR in commercial vehicle production. As radial tires claim 89% market share across developed economies, manufacturers require steel cords with 3,400-3,800 MPa tensile strength for high-speed endurance. This demand fuels innovation among 160+ certified suppliers worldwide, particularly in Southeast Asia where export volumes grew 14.6% YoY.

Breaking Limits: High-Strength Material Engineering

Advanced tire cord steel utilizes patented micro-alloying technology:

- 0.82% carbon content for structural integrity

- Vanadium-nitrogen compounds enhancing fatigue resistance by 40%

- Drawn to 0.15-0.38mm diameter with ±0.003mm tolerance

Third-party testing confirms 23% longer lifecycle versus conventional cords in 75-series truck tires under 120km/h sustained operation.

Supplier Capability Matrix

| Manufacturer | Production Capacity | Certifications | Key Markets |

|---|---|---|---|

| SteelFlex Corp | 180,000 MT/year | IATF 16949, AD2000 | EU, NAFTA |

| AsianCord Ltd | 420,000 MT/year | JIS G3503, ISO 14272 | ASEAN, Oceania |

| TyreCore Solutions | 95,000 MT/year | GOST 14918 | CIS, MENA |

Precision Customization Protocols

Leading tire cord steel manufacturers now offer:

- Alloy composition adjustment (±0.05% element variation)

- Zinc-coated variants for humidity resistance (3-8μm coating)

- Pre-weaved cord mats for automated tire assembly lines

A European tire maker reduced production waste by 18% through customized 0.22mm steel cords matching their vulcanization parameters.

Global Distribution Channels Optimized

Major exporters maintain 35 strategic warehouses worldwide, ensuring 96.7% on-time delivery through:

- Climate-controlled container shipping

- Blockchain-tracked inventory systems

- Regional technical support centers

Real-World Application: Mining Vehicle Tires

A joint development with BHP Group achieved:

| Parameter | Before | After |

|---|---|---|

| Cut Resistance | Level 5 | Level 8 |

| Retread Cycles | 2 | 4 |

Tire Cord Steel Suppliers Driving Circular Economy

Top manufacturers now recover 92% of production scrap through electric arc furnaces, reducing CO₂ emissions by 2.3 tons per 1000 MT output. The industry moves toward 100% recyclable steel cords as Michelin and Bridgestone adopt closed-loop systems with preferred suppliers.

(tire cord steel)

FAQS on tire cord steel

Q: What is tire cord steel used for in manufacturing?

A: Tire cord steel is a high-strength material embedded in rubber tires to reinforce their structure, improve durability, and enhance load-bearing capacity. It ensures stability and safety in automotive applications.

Q: How to identify reliable tire cord steel suppliers?

A: Reliable tire cord steel suppliers should offer certified materials (e.g., ASTM/JIS standards), have a proven track record, and provide technical support. Verify certifications and client testimonials to ensure quality.

Q: What certifications do top tire cord steel manufacturers hold?

A: Top manufacturers typically hold ISO 9001, IATF 16949, and environmental certifications like ISO 14001. These ensure compliance with global quality, automotive, and sustainability standards.

Q: Which countries are key markets for tire cord steel exporters?

A: Major markets include the U.S., Germany, Japan, China, and India. These regions have high automotive production demands and stringent quality requirements for tire reinforcement materials.

Q: What factors affect tire cord steel performance in tires?

A: Key factors include tensile strength, adhesion to rubber, corrosion resistance, and fatigue resistance. Manufacturers optimize these properties through alloy composition and specialized coating processes.

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025