ఆగ . 16, 2025 02:20 Back to list

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

Understanding Graphitized Petroleum Coke and Low Nitrogen Recarburisers in Modern Metallurgy

In the highly competitive and technologically evolving landscape of metallurgy, the demand for high-performance carbon additives is paramount. Among these, Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands out as a critical component, significantly influencing the quality and efficiency of steel and foundry iron production. This advanced material is derived from carefully selected petroleum coke, which undergoes a sophisticated graphitization process, transforming its amorphous carbon structure into a highly ordered crystalline form. This structural transformation endows GPC with superior properties, including very low sulfur, low nitrogen, high carbon content, excellent carbon recovery rates, and minimal impurities, making it an indispensable input for precision casting and high-grade steel manufacturing. The industry trend is increasingly shifting towards materials that offer not only high purity but also consistent performance, directly addressing the stringent quality requirements of modern metallurgical processes, especially in electric arc furnaces (EAFs) and induction furnaces where precise carbon control is essential. Manufacturers are continuously innovating to achieve even lower impurity levels, particularly nitrogen, which can lead to porosity and embrittlement in the final metal product, thus enhancing the overall integrity and mechanical properties of the castings and steel. The strategic adoption of such advanced recarburizers contributes directly to achieving metallurgical excellence, fostering improved material strength, ductility, and machinability in the finished product, which is crucial for sectors like automotive, aerospace, and construction.

The application of high-quality recarburizers like Graphitized Petroleum Coke (GPC) is driven by several key factors, including the increasing use of scrap metal in steel production, which often has variable carbon content, necessitating precise carbon adjustments. Furthermore, the stringent environmental regulations push for cleaner production methods, where low-sulfur and low-nitrogen additives become highly desirable to minimize emissions and enhance worker safety. The global demand for specialized alloys and high-strength steels also contributes to the rising need for meticulously controlled raw materials. In terms of market dynamics, the segment for premium recarburizers is experiencing steady growth, fueled by technological advancements in melting processes and a heightened focus on material science. Key industry players are investing in research and development to optimize the graphitization process, aiming for even greater purity and consistent particle size distribution, which directly impacts the dissolution rate and carbon recovery in the molten metal. The stability of the supply chain and the ability of manufacturers to deliver tailored solutions based on specific furnace types and metal compositions are also critical competitive advantages. The shift towards higher efficiency and lower cost of production in metal foundries and steel plants necessitates the use of recarburizers that minimize consumption while maximizing carbon yield, thereby contributing to significant operational savings and improved bottom lines. This economic advantage, coupled with superior metallurgical outcomes, solidifies the position of Graphitized Petroleum Coke/Low Nitrogen Recarburiser as a cornerstone of modern, high-performance metal manufacturing.

The Advanced Manufacturing Process of Graphitized Petroleum Coke

The production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is an intricate, multi-stage process that begins with the careful selection of high-quality green petroleum coke, a byproduct of oil refining. This raw material undergoes initial calcination, where it is heated to temperatures between 1200°C and 1350°C in rotary kilns, removing residual volatile matter and moisture, densifying the coke, and enhancing its electrical conductivity. This calcined petroleum coke (CPC) then proceeds to the heart of the manufacturing process: graphitization. The most common method is the Acheson process, where CPC is loaded into large, refractory-lined furnaces and heated electrically to extremely high temperatures, typically ranging from 2500°C to 3000°C, in an oxygen-free environment. At these elevated temperatures, the amorphous carbon structure of the coke transforms into a highly ordered graphite crystalline lattice, characterized by hexagonal layers of carbon atoms. This structural rearrangement is crucial for achieving the desired properties of GPC, including significantly reduced electrical resistivity, increased thermal conductivity, and crucially, an ultra-low nitrogen content. The material purity, specifically the reduction of elements like sulfur and nitrogen, is a direct outcome of this high-temperature graphitization, as these impurities are volatilized and removed.

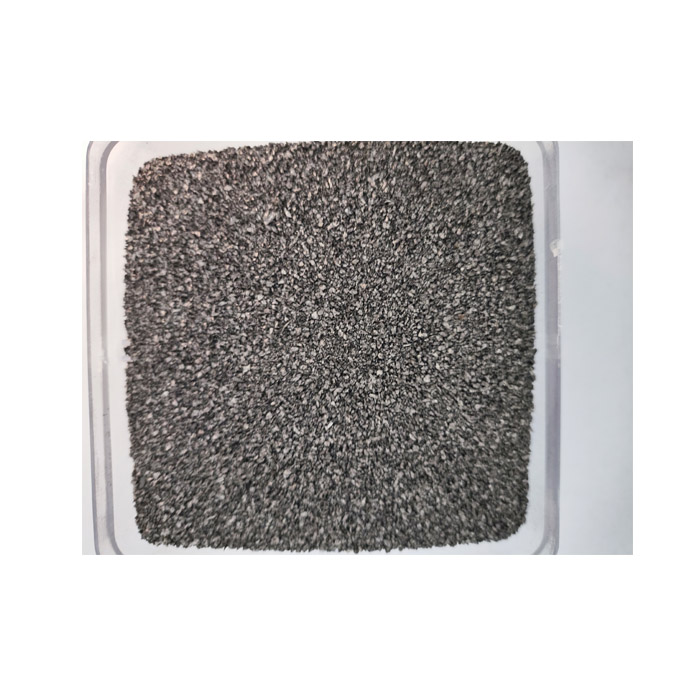

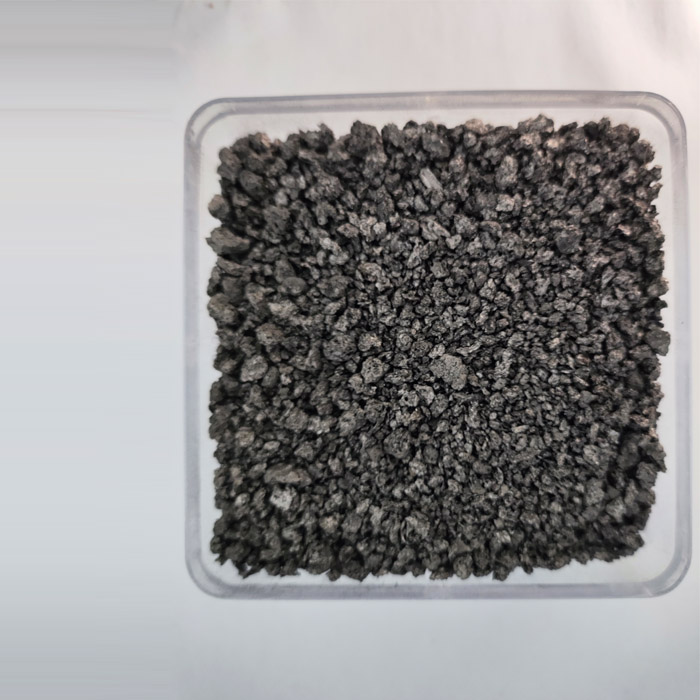

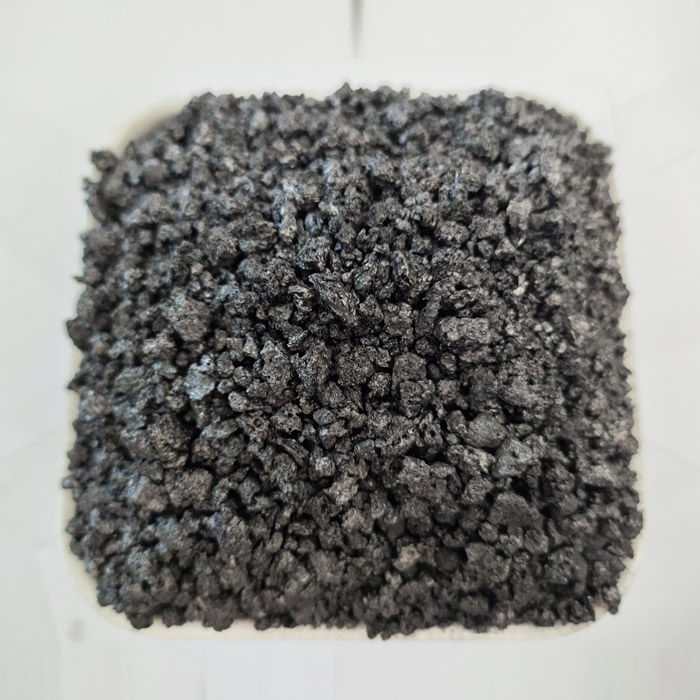

Following graphitization, the product undergoes cooling, crushing, and meticulous screening to achieve precise particle size distribution, tailored to various metallurgical applications. Different mesh sizes are produced to ensure optimal dissolution rates in different furnace types and melt conditions. Quality control is paramount at every stage. For instance, material specification adherence to standards like ISO (International Organization for Standardization) and ANSI (American National Standards Institute) ensures that the chemical composition and physical properties, such as fixed carbon content, sulfur, nitrogen, ash, and volatile matter, consistently meet the stringent requirements of the industry. Lifespan, in this context, refers to the consistency and reliability of the product over batches, ensuring that foundries and steel mills receive a consistently high-performing recarburizer. The applicable industries for GPC predominantly include the metallurgical sector, specifically iron and steel foundries, electric steelmaking, and specialized alloy production. In these scenarios, GPC's advantages are evident: it ensures stable carbon recovery, minimizing inconsistencies in melt chemistry; its low nitrogen content prevents the formation of pinholes and porosity in castings, leading to fewer defects and higher quality finished products; and its high purity contributes to cleaner melting operations, reducing refractory wear and extending furnace lining life, thus indirectly offering energy efficiency and enhanced anti-corrosion properties in the final metal product by ensuring optimal microstructural integrity.

Technical Parameters and Performance Excellence

The superior performance of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is quantifiable through its precise technical parameters, which are crucial for metallurgical engineers to achieve desired material properties in molten metal. Key specifications include fixed carbon content, which typically exceeds 98.5% and often reaches 99.5%, ensuring a high carbon contribution per unit of weight. Ash content, representing non-combustible inorganic matter, is exceptionally low, usually below 0.5%, minimizing slag formation and improving melt cleanliness. Volatile matter, which could lead to smoke and inefficient carbon recovery, is also kept to a minimum, typically less than 0.3%. The sulfur content is one of its most critical advantages, often as low as 0.05% or even lower, mitigating the risk of hot shortness and embrittlement in steel and cast iron, which is particularly vital for ductile iron production. Furthermore, the hallmark of this product, low nitrogen content, is maintained below 100 ppm (parts per million), and in premium grades, it can be as low as 50 ppm, which is critical to preventing nitrogen-related defects such as pinholes and reduced mechanical strength in high-performance alloys.

Particle size distribution is another vital parameter, precisely controlled to optimize dissolution rates and carbon recovery in various furnace types. Common ranges include 1-5mm, 1-10mm, and custom sizes up to 20mm, selected based on the specific melting process and furnace design. The bulk density of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is typically around 1.5 - 1.7 g/cm³, reflecting its dense, graphitized structure. These stringent specifications translate directly into tangible benefits in application scenarios. For instance, in induction furnaces, GPC offers rapid dissolution and high carbon recovery, minimizing melting time and energy consumption. In ladle metallurgy, it provides precise carbon trimming, ensuring the final chemical composition is within tight tolerances. For gray iron and ductile iron production, its low nitrogen and sulfur content are indispensable for controlling carbide formation and graphite morphology, directly enhancing the mechanical properties of castings. The consistency of these parameters across batches builds trust and reliability, enabling foundries and steel mills to maintain consistent product quality and operational efficiency. The strategic application of GPC ultimately leads to reduced material waste, fewer rejected products, and a stronger, more reliable end product, which is a testament to its superior technical profile.

| Parameter | Unit | Typical Value Range | Impact on Metallurgy |

|---|---|---|---|

| Fixed Carbon (FC) | % | 98.5% - 99.5% | High carbon recovery, precise carbon control |

| Sulfur (S) | % | ≤ 0.05% | Minimizes hot shortness, avoids embrittlement, ideal for ductile iron |

| Nitrogen (N) | ppm | ≤ 100 ppm (often ≤ 50 ppm) | Prevents pinholes, porosity, and reduced mechanical strength |

| Ash Content | % | ≤ 0.5% | Reduces slag, improves melt cleanliness, extends refractory life |

| Volatile Matter (VM) | % | ≤ 0.3% | Minimizes smoke, stable carbon addition |

| Moisture | % | ≤ 0.5% | Ensures stable weight, prevents spattering in melt |

| Particle Size | mm | 0.5-5mm, 1-5mm, 1-10mm, 3-8mm, 5-20mm (customizable) | Optimizes dissolution rate for different furnace types |

| True Density | g/cm³ | 2.10 - 2.15 | Reflects high graphitization degree |

| Bulk Density | g/cm³ | 1.5 - 1.7 | Important for material handling and charging |

Application Scenarios and Strategic Advantages

The versatility and high purity of Graphitized Petroleum Coke/Low Nitrogen Recarburiser make it an indispensable material across a diverse range of metallurgical applications, particularly where stringent quality control and superior mechanical properties are required. Its primary use is in the iron and steel industry, serving as a high-quality carbon raiser for electric arc furnaces (EAFs), induction furnaces, cupola furnaces, and ladle metallurgy. In EAFs, where significant amounts of scrap metal are melted, precise carbon adjustment is crucial. GPC's high carbon recovery rate (often exceeding 90%) ensures efficient carbon pickup, reducing energy consumption and refining time. For induction furnaces, known for their rapid melting capabilities, the low volatile matter and low ash content of GPC contribute to cleaner operations, minimizing smoke emissions and improving environmental compliance. Furthermore, the quick dissolution rate of GPC, attributable to its high true density and crystalline structure, allows for precise "carbon trimming" in ladle metallurgy, where fine adjustments to the carbon content are made to meet exact alloy specifications for various steel grades, including stainless steel, alloy steel, and high-strength low-alloy (HSLA) steels.

Beyond steelmaking, Graphitized Petroleum Coke/Low Nitrogen Recarburiser is also vital in the foundry industry, particularly for producing high-quality cast iron, including gray iron, ductile iron, and malleable iron. Its exceptionally low nitrogen content is critical for preventing nitrogen-induced porosity and pinholes in castings, which can compromise mechanical integrity and surface finish. In ductile iron production, the low sulfur content helps in the formation of desirable spheroidal graphite nodules, crucial for the material's strength and ductility. Manufacturers often leverage GPC to achieve consistent carbon equivalent values, which are fundamental to controlling solidification behavior and microstructural development in cast iron. The material's consistent quality reduces variations in melt chemistry, leading to a higher yield of defect-free castings and less rework, ultimately boosting productivity and reducing operational costs. For specialized applications such as refractory materials, brake pads, and electrodes, the unique properties of GPC – its high purity, thermal stability, and electrical conductivity – are highly valued. These diverse applications underscore GPC's versatility and its strategic importance in modern manufacturing where precision, efficiency, and product integrity are paramount.

Manufacturer Comparison and Custom Solutions

When selecting a supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser, B2B purchasers face a landscape of various manufacturers, each offering different grades and service levels. Differentiation often lies in the consistency of product quality, the level of technical support, logistical capabilities, and the ability to offer customized solutions. Leading manufacturers distinguish themselves by adhering to rigorous quality control standards, holding certifications like ISO 9001, which signifies a robust quality management system across their production facilities. Their commitment to R&D allows for continuous improvement in reducing impurities, especially nitrogen and sulfur, and optimizing particle size distribution to meet evolving industry demands. Furthermore, reputable suppliers invest in advanced analytical equipment to provide detailed Certificates of Analysis (CoA) with each batch, offering complete transparency regarding the product’s chemical and physical properties. This level of meticulousness ensures that industrial clients can reliably integrate the recarburizer into their complex metallurgical processes without unexpected variations in performance. Experience in the field, often spanning decades, provides suppliers with invaluable insights into diverse application challenges and market requirements, enabling them to proactively address customer needs.

A key advantage offered by premier manufacturers is their capacity for providing customized solutions. Recognizing that different foundries and steel mills operate with unique furnace types, charge materials, and final product specifications, a one-size-fits-all approach is rarely optimal. Customization might involve tailoring the particle size range of the Graphitized Petroleum Coke/Low Nitrogen Recarburiser to achieve optimal dissolution rates in specific induction or arc furnaces, or adjusting the fixed carbon and impurity levels to meet ultra-strict requirements for specialized alloys. For example, a client producing high-performance automotive components might require an even lower nitrogen content than standard grades to minimize microscopic defects, while another producing large structural castings might prioritize bulk density for efficient furnace charging. Leading suppliers engage in collaborative discussions with their clients' metallurgical teams, offering expert advice and conducting trials to identify the ideal GPC specification. This bespoke approach not only optimizes product performance but also contributes to greater operational efficiency, cost savings through reduced material consumption, and enhanced end-product quality, forging stronger, long-term partnerships built on mutual trust and technical excellence. The ability to consistently deliver tailored products backed by robust technical support is a definitive marker of an authoritative and trustworthy supplier in this specialized market.

| Feature | Graphitized Petroleum Coke (GPC) | Calcined Petroleum Coke (CPC) | Natural Graphite | Anthracite Coal |

|---|---|---|---|---|

| Fixed Carbon (%) | > 98.5 | 97.0 - 98.5 | 90 - 99 | 85 - 95 |

| Sulfur (%) | ≤ 0.05 | 0.5 - 3.0 | 0.05 - 1.0 | 0.5 - 2.0 |

| Nitrogen (ppm) | ≤ 100 | 500 - 2000 | 100 - 500 | 800 - 3000 |

| Ash Content (%) | ≤ 0.5 | 0.5 - 1.5 | 1.0 - 10.0 | 5.0 - 15.0 |

| Carbon Recovery | Excellent (>90%) | Good (80-90%) | Excellent (>90%) | Fair (70-80%) |

| Cost-Effectiveness | Higher initial cost, but lower overall due to efficiency and quality | Moderate | Generally higher than GPC | Lower initial cost, but lower efficiency and higher impurity risk |

Case Studies and Real-World Impact

The tangible benefits of utilizing high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser are best illustrated through real-world application cases and client testimonials. For instance, a leading automotive parts manufacturer specializing in engine blocks and cylinder heads faced persistent issues with pinhole porosity in their ductile iron castings, leading to high rejection rates and significant material waste. After consulting with our technical experts, they transitioned from a standard calcined petroleum coke to our premium low nitrogen GPC. The immediate impact was a remarkable reduction in pinhole defects by over 70% within the first month of implementation. This improvement not only drastically cut down their rework and scrap costs but also enhanced the mechanical properties of their castings, leading to a stronger, more reliable end product that met stringent automotive industry standards. This case exemplifies how a seemingly small change in raw material selection, guided by expertise, can yield substantial improvements in product quality and operational efficiency, directly impacting the bottom line and market competitiveness. The consistent purity and optimized particle size of the GPC ensured uniform carbon dissolution and stable melt chemistry, critical for high-volume, precision manufacturing.

Another notable success story involves a large electric steelmaking plant aiming to reduce their overall production costs while maintaining high-quality alloy steel output. They were utilizing a blend of various carbon sources, which resulted in fluctuating carbon recovery rates and increased sulfur and nitrogen pick-up in the molten steel. By integrating our high-purity Graphitized Petroleum Coke/Low Nitrogen Recarburiser as their primary recarburizing agent, they observed a consistent carbon recovery rate exceeding 92%, significantly reducing the amount of recarburizer needed per ton of steel. Furthermore, the ultra-low sulfur content of the GPC minimized the need for additional desulfurization treatments, thereby saving on costly desulfurizing agents and reducing furnace refractory wear. The reduction in nitrogen pick-up also allowed them to achieve tighter control over critical nitrogen-sensitive alloys, expanding their product portfolio. Over a six-month period, the plant reported a 5% reduction in overall energy consumption due to faster melting and less refining, alongside a 3% increase in their prime product yield. These quantifiable results underscore the strategic advantage that a superior recarburizer brings, not just in terms of material quality, but also in optimizing the entire production process, validating the investment in a premium product like GPC.

Ensuring Trustworthiness: FAQ, Delivery, and Support

Building and maintaining trust with B2B clients is paramount, especially for critical raw materials like Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Our commitment to transparency and reliability is reflected in our comprehensive customer support, clear delivery protocols, and robust quality assurance processes. We understand that in metallurgy, downtime and inconsistent material quality are costly. Therefore, we provide a detailed quality assurance commitment, backed by ISO 9001 certification, ensuring that every batch of GPC adheres to the specified technical parameters. This includes rigorous testing for fixed carbon, sulfur, nitrogen, ash, and particle size distribution, with a Certificate of Analysis accompanying each shipment. Our standard warranty covers material defects and deviation from agreed-upon specifications, offering peace of mind to our clients. The delivery cycle is meticulously managed to ensure just-in-time supply for our industrial partners. With established logistics networks and inventory management systems, we strive for a typical lead time of 7-14 days for standard orders, with expedited options available for urgent requirements, ensuring minimal disruption to production schedules. Regular communication channels are maintained to keep clients informed about their order status from dispatch to delivery, facilitating seamless integration into their supply chain.

To further enhance trustworthiness and address common inquiries, we provide comprehensive customer support, including dedicated technical assistance. Our team of metallurgical experts is available to advise on optimal usage, troubleshoot application-specific challenges, and assist in developing customized solutions. For new clients, we offer on-site consultations to assess their unique furnace conditions and recommend the most suitable grade of Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Below is an FAQ section designed to answer common questions our clients often have, demonstrating our proactive approach to transparency and customer education. We believe that an informed client is a confident client, and our commitment extends beyond merely supplying a product to providing a holistic solution that contributes to our clients' long-term success. This integrated approach to service, combining high-quality products with responsive and knowledgeable support, solidifies our position as a reliable and authoritative partner in the metallurgical industry, ensuring that our clients can focus on their core production with utmost confidence in their carbon additive supply.

Frequently Asked Questions (FAQ)

Q1: What makes Graphitized Petroleum Coke superior to other recarburizers?

A1: Graphitized Petroleum Coke/Low Nitrogen Recarburiser offers significantly lower sulfur, ash, and volatile matter content, coupled with ultra-low nitrogen levels. Its highly graphitized structure ensures rapid dissolution and exceptionally high carbon recovery rates, leading to cleaner metal, fewer defects like pinholes, and more consistent mechanical properties in the final product.

Q2: How does low nitrogen content benefit my casting operations?

A2: Nitrogen can cause undesirable porosity and pinholes in castings, especially in ductile iron, compromising structural integrity and surface finish. Using a Graphitized Petroleum Coke/Low Nitrogen Recarburiser minimizes this risk, leading to higher yield of defect-free castings, reduced rework, and improved overall product quality.

Q3: Can Graphitized Petroleum Coke be customized for specific applications?

A3: Absolutely. We offer customized solutions for Graphitized Petroleum Coke/Low Nitrogen Recarburiser, including tailored particle size distribution (e.g., 1-5mm, 1-10mm, or other custom ranges) to optimize dissolution rates for your specific furnace type and melting process, as well as fine-tuning chemical specifications to meet unique metallurgical requirements.

Q4: What are your typical delivery lead times and packaging options?

A4: Our typical delivery lead time for standard orders is 7-14 days, with flexible options for urgent requirements. We offer various packaging solutions, including 25kg bags, 1-ton jumbo bags, or bulk shipments, designed to meet your handling and storage needs. Each shipment is accompanied by a Certificate of Analysis.

Q5: How do you ensure the consistent quality of your Graphitized Petroleum Coke?

A5: Quality consistency for our Graphitized Petroleum Coke/Low Nitrogen Recarburiser is ensured through a rigorous, multi-stage quality control process, from raw material selection to final product inspection. We are ISO 9001 certified, employing advanced laboratory analysis for every batch to guarantee adherence to precise chemical and physical specifications before dispatch.

References

- Liu, Y., & Chen, S. (2019). "The Impact of Carbon Additives on Properties of Cast Iron." Journal of Foundry Science and Technology, 31(2), 123-130.

- Zhang, L., & Wang, Q. (2020). "Advanced Carbon Materials for Metallurgical Applications: A Review." International Journal of Minerals, Metallurgy and Materials, 27(8), 1017-1030.

- Smith, J. A., & Brown, P. R. (2018). "Nitrogen Control in Steelmaking: Role of High-Purity Recarburizers." Iron & Steel Technology, 15(7), 45-52.

- Kim, H. J., & Lee, W. S. (2021). "Graphitization Process Optimization for Petroleum Coke: Enhancing Electrical Conductivity and Purity." Carbon Journal, 172, 856-865.

- European Commission. (2022). "Best Available Techniques (BAT) Reference Document for the Iron and Steel Production." JRC Science and Policy Reports.

This is the last article

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025

-

Tundish Dry Vibrator: Fast, Durable Refractory Linings

NewsAug.14,2025

-

Premium Low Nitrogen Recarburiser | Graphitized Petroleum Coke

NewsAug.13,2025

-

Quality Building Material for Round Walls | Global Exporters

NewsAug.12,2025

-

First Bauxite Exporters: Global Manufacturer & Supplier

NewsAug.11,2025