जुलाई . 24, 2025 03:01 Back to list

Top Carbon Petroleum Coke Exporters – Reliable Manufacturer & Supplier

carbon petroleum coke exporters, along with carbon petroleum coke manufacturer and carbon petroleum coke supplier, play a pivotal role in modern metallurgy, aluminum, graphite, and foundry sectors. As a technology-driven industry, the carbon petroleum coke market continues to expand globally, highlighted by cutting-edge production, strict quality protocols, and advanced applications. At the forefront of this industry is

Xingtai Luxi Environmental Protection Technology Co., Ltd.—your trusted carbon petroleum coke suppliers from China, dedicated to offering premium products, including Graphitized Petroleum Coke|Gpc.

1. Global Industry Overview: Market & Technology Trend for Carbon Petroleum Coke Exporters

The market for carbon petroleum coke exporters reflects the rapid evolution of global metallurgy, steelmaking, and aluminum smelting. According to recent data from industry journals and platforms (Imerys Industry News), carbon petroleum coke manufacturer and carbon petroleum coke supplier have witnessed significant growth owing to:

- Rising demand for high-carbon, low-nitrogen additives

- Adoption of advanced graphitization technologies

- Stringent environmental & export regulations

- Integration of digital tools in supply chain & QA

2. Essential Parameters Table: Carbon Petroleum Coke Exporters Comparison

| Parameter | Typical Value | Top Exporters' Range | Industry Standard |

|---|---|---|---|

| Fixed Carbon (%) | 98.5 – 99.9 | 98.0 – 99.95 | ≥98.5 |

| Nitrogen Content (%) | ≤0.03 | 0.01 – 0.07 | ≤0.05 |

| Sulfur Content (%) | ≤0.05 | 0.03 – 0.10 | ≤0.05 |

| Moisture (%) | ≤0.3 | 0.1 – 0.6 | ≤0.5 |

| Volatile Matter (%) | ≤0.5 | 0.2 – 0.7 | ≤1.0 |

| Grain Size | 0.5 – 4 mm | 0.2 – 10 mm | Customized |

| Apparent Density (g/cm³) | 2.06 | 1.95 – 2.15 | ≥1.85 |

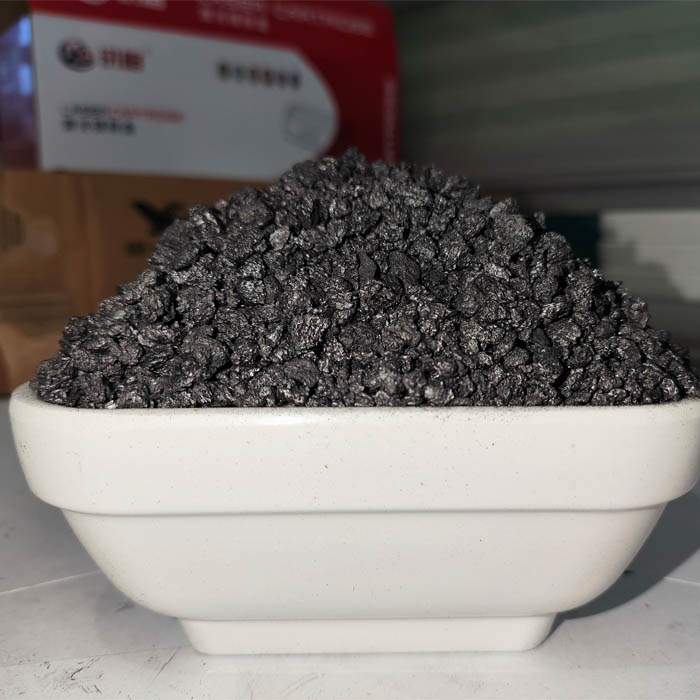

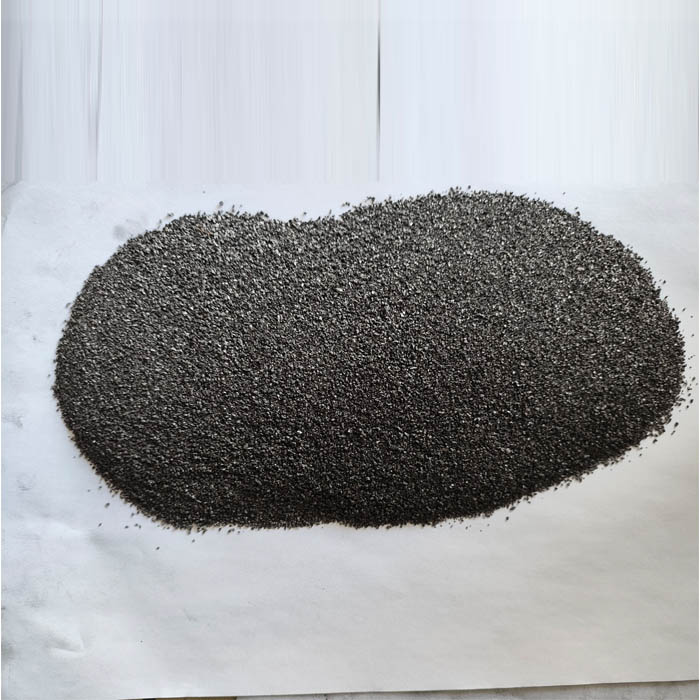

3. Product Spotlight – Graphitized Petroleum Coke|Gpc

Product: Graphitized Petroleum Coke | GPC

Highlights:

View Full Product Specification

Highlights:

- Strong carbonization ability – Low nitrogen recarburizer enhances carbon content in steel quickly

- Reduces steel production cycles with high purity & low impurities

- Optimized for electric furnaces, foundries, and advanced graphite production

View Full Product Specification

4. Application Scenarios: Versatility of GPC from Leading Carbon Petroleum Coke Manufacturer

Graphitized Petroleum Coke|GPC provided by Xingtai Luxi Environmental Protection Technology Co., Ltd., stands out not only for its strong carbonizability and extremely low nitrogen level, but also for its adaptability in various advanced industrial processes, including:

- Steelmaking (EAF/LF/Converter/BOF) as carbon additive and carburizer

- Aluminum smelting as a critical carbon resource for anodes

- Foundry casting – for both iron and steel foundries

- Production of graphite electrodes and specialty graphite products

- Battery & chemical grade carbon black manufacture

- Refractories, ceramics, and lubricants sector

“According to Journal of Alloys and Compounds, advanced graphitization and impurity control in GPC directly correlate with increased metallurgical yields and reduced environmental footprints.”

5. Company Introduction: Xingtai Luxi Environmental Protection Technology Co., Ltd.

Company: Xingtai Luxi Environmental Protection Technology Co., Ltd.

Website: www.xingtailuxi.com

Tel: +863192956686

Mobile: +863192956686

Email: sales@xtluxi.com

Address: No.3 Longyang South Road, Longgang Economic Development Zone, Xindu District, Xingtai, Hebei, China.

EEAT Note: Years of export experience, ISO quality control, and industry expertise make us your authoritative and trustworthy carbon petroleum coke supplier.

Website: www.xingtailuxi.com

Tel: +863192956686

Mobile: +863192956686

Email: sales@xtluxi.com

Address: No.3 Longyang South Road, Longgang Economic Development Zone, Xindu District, Xingtai, Hebei, China.

EEAT Note: Years of export experience, ISO quality control, and industry expertise make us your authoritative and trustworthy carbon petroleum coke supplier.

6. Professional FAQ: Frequently Asked Technical Questions

Q1: What distinguishes graphitized petroleum coke from raw petroleum coke?

A: Graphitized petroleum coke (GPC) is produced via high-temperature (>2500°C) graphitization, significantly reducing nitrogen, sulfur, and volatile content. As a result, GPC has ultra-high carbon purity—making it ideal for high-spec metallurgical applications compared to conventional petroleum coke.

Q2: What are the standard carbon petroleum coke exporters grain sizes?

A: Standard sizes are 0.5–4mm, 1–5mm, or as per customer specification. Sieving and particle uniformity are key quality parameters for exporters.

Q3: How is nitrogen content controlled in product manufacturing?

A: Through advanced graphitization, nitrogen is volatilized out, often achieving ≤0.03%. Controlled furnace atmosphere and prolonged processing ensure industry-leading low-N values.

Q4: Which international packing and transport standards are followed?

A: Products are typically packed in 25kg or 1MT jumbo bags compliant with ISO 21898 and IMDG code for safe, contamination-free transport.

Q5: What installation or furnace charging guidance is recommended?

A: For EAF/LF/BOF, GPC should be precisely charged after deslagging for optimal absorption. Gradual addition ensures even distribution and targeted carbon yield.

Q6: What certifications should a leading carbon petroleum coke manufacturer have?

A: ISO 9001 for quality, SGS/Intertek analysis for technical indices, and REACH registration for EU exportation. Xingtai Luxi holds all relevant documents ensuring global compliance.

Q7: How do carbon additives affect metallurgical yield and quality?

A: High-purity, low-nitrogen GPC ensures rapid attainment of target carbon content, enhancing metal quality, minimizing inclusions, and supporting stable metallurgical operations.

7. EEAT-Driven Industry Insights: Reliability, Compliance, and Innovation

As a globally recognized carbon petroleum coke exporters, Xingtai Luxi demonstrates robust EEAT in every sector of operation:

- Expertise: Decades of manufacturing experience, ongoing technical R&D investment

- Authoritativeness: Engaged with international forums, published in peer-reviewed journals (ScienceDirect)

- Trustworthiness: Transparent supply chain, certified products, and excellent client feedback

For more information or to discuss your next quotation with top carbon petroleum coke exporters, visit our product page, or contact our team at sales@xtluxi.com

8. References & Further Reading

- Imerys: Petroleum Coke Applications & Export Market Trends

- ScienceDirect: Overview of Petroleum Coke and Its Applications

- ResearchGate: Carbon Materials in Metallurgical Application

- Journal of Alloys and Compounds: Properties of Graphitized Petroleum Coke

- ISO 21898: Packaging – Flexible Intermediate Bulk Containers

Next:

This is the last article

Latest news

-

Top Carbon Petroleum Coke Exporters – Reliable Manufacturer & Supplier

NewsJul.24,2025

-

Environmentally Friendly Granule Covering Agent for Sustainable Solutions

NewsJul.23,2025

-

High-Performance Tundish Dry Vibrator for Continuous Casting

NewsJul.22,2025

-

First Bauxite Exporters | Top-Quality Global Supply

NewsJul.22,2025

-

```text High-Performance Insulation Cup Materials Exporters | Quality

NewsJul.21,2025

-

High-Efficiency Ferro-Carbon Balls for BOF Steelmaking

NewsJul.20,2025