7-р сар . 30, 2025 00:00 Back to list

Top Carbon Petroleum Coke Exporters – Reliable Quality & Fast Delivery

The global market for carbon petroleum coke exporters has been experiencing robust growth, propelled by increasing demand across metallurgy, chemical, and energy sectors. As sustainability and high-performance materials become paramount, Graphitized Petroleum Coke | GPC has emerged as a preferred product for its superior carbon content and excellent conductivity. With manufacturers and carbon petroleum coke suppliers across regions such as China, USA, and India, the choice of exporter hinges on material quality, certification standards, and technological innovation.

- Global Petroleum Coke Market Size (2023): $25.8 billion

Projected CAGR (2024-2030): 5.5% - Main Segments of Use: Steelmaking, Aluminum Smelting, Ferroalloys, Foundries

- Top Export Hubs: China (65% share), USA, India

- Technology Focus: High-purity graphitization, low sulfur, customized sizing

- Primary Certifications: ISO 9001, ANSI, SGS, ROHS

What Makes Graphitized Petroleum Coke | GPC Exceptional?

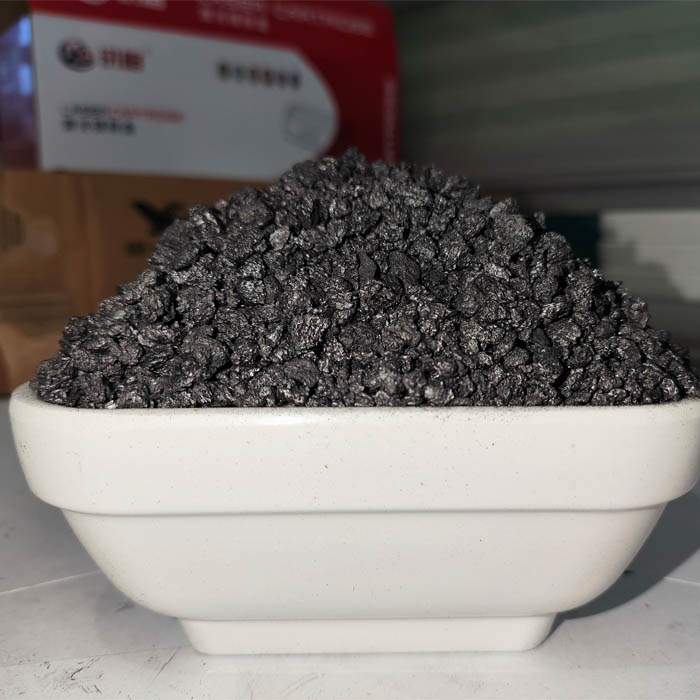

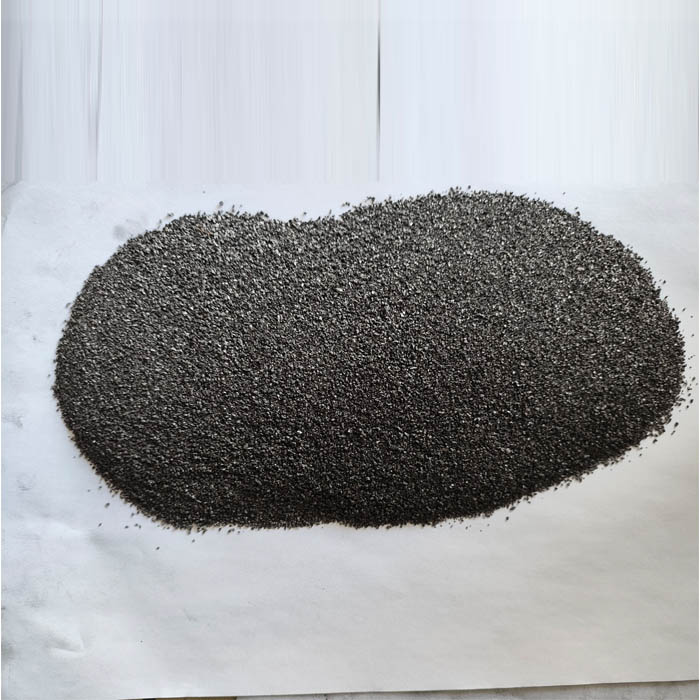

Graphitized Petroleum Coke (GPC) is a high-purity carbon material derived from petroleum coke after high-temperature graphitization. Its crucial features—ultra-high fixed carbon (≥98.5%), very low sulfur content (≤0.05%), superb electrical conductivity—make it indispensable for industries requiring premium carbon input.

- Material: High-purity petroleum coke, fully graphitized

- Manufacturing Process: Calcination, graphitization, crushing & sieving, quality inspection

- Applications: Steelmaking, foundry, aluminum, electrodes, lithium battery anodes

- Advantages: Energy savings, ultra-low impurity, corrosion resistance, customizable sizing

Comparative Table: Key Parameters of Carbon Petroleum Coke Exporters (2024)

| Exporter | Fixed Carbon (%) | Sulfur (%) | Ash (%) | Volatile Matter (%) | Particle Size (mm) | Certifications |

|---|---|---|---|---|---|---|

| Luxi Chemical (China) | 98.5 | 0.05 | 0.2 | 0.5 | 0.5-5 | ISO 9001, SGS |

| CPC Corp (USA) | 98.2 | 0.1 | 0.3 | 0.6 | 1-3 | ANSI, ROHS |

| PetroSim (India) | 98.0 | 0.07 | 0.4 | 0.4 | 1-5 | ISO 9001 |

| EuroCarb (EU) | 97.9 | 0.12 | 0.5 | 0.7 | 0.5-5 | SGS, CE |

Visualizing Technology Trends Among Carbon Petroleum Coke Exporters

Manufacturing Process Flow of Carbon Petroleum Coke Exporters (Graphitized Petroleum Coke | GPC)

Low sulfur, high C input Crushing & Pre-Screening

Particle size: 0.5-5mm Calcination

Temp: 1300°C, Volatiles Graphitization

Temp: 3000°C, Conversion to graphite Secondary Screening

Size uniformity, ISO/ANSI checks Quality Inspection

Certs: ISO 9001, SGS, ASTM Packaging & Shipping

Moisture-proof, customized bags

- Critical Control Points: Graphitization temperature (optimize structure), sulfur removal, strict particle size grading (optical sorting), ISO batch testing

- Standard Compliance: Meets latest ISO 9001, ANSI Industry Standards, third-party SGS verification

- Custom Options: Surface treatment (anti-oxidation), particle size modification, tailored packaging

Applications & Technical Advantages of Graphitized Petroleum Coke | GPC

| Industry Segment | GPC Application | Benefits | Performance |

|---|---|---|---|

| Steelmaking | Carbon additive in EAF/LF/BOF; reduces impurities | Boosts carbon recovery, ensures fast dissolution | 98.5%-99% C recovery, ≤0.05% S |

| Aluminum Smelting | Used in cathode blocks, anode production | Minimizes anode effect, enhances conductivity | 10%+ increased current efficiency |

| Foundry Casting | Graphite inoculant, nodularizer | Promotes uniform microstructures | Reduces casting defects by 25%+ |

| Lithium Battery | Anode material, carbon source | Ultra-high purity, battery-grade | 99%+ carbon, <5ppm metals |

- Corrosion Resistance: Graphitic layers form natural protection in acidic/alkali environments.

- Energy Savings: Low resistivity (≤6 μΩ·m), reduces energy loss in EAFs.

- Service Life: 15-25% longer lifespan versus standard calcined petroleum coke (CPC).

Graphitized Petroleum Coke | GPC Main Technical Parameters (Pie & Line Charts)

Comparing Leading Carbon Petroleum Coke Exporters & Customization Capabilities

- Luxi Chemical (China): Top-tier carbon petroleum coke exporter with full graphitization line and ISO+SGS certification. Custom sieving from 0.5–10 mm, anti-oxidation upgrades.

- Competitor A (USA): Focus on battery-grade GPC. Higher price but limited particle size options. Meets ANSI standards.

- Competitor B (India): Volume supplier, strong for steel industry, slower on niche customizations.

- Value Add: Luxi’s team offers rapid technical consultation, test reports, and case-based recommendations.

| Supplier | Custom Sizing | Anti-Ox Treatment | Delivery Time | After-Sales Support |

|---|---|---|---|---|

| Luxi Chemical | Yes (0.5 mm-15 mm) | Yes (optional) | 2-4 weeks | 24/7 engineer online, ISO warranty |

| Competitor A | No (fixed 1-3 mm) | No | 5-7 weeks | Email only, limited |

| Competitor B | Yes (1-10 mm) | Limited | 3-5 weeks | Standard business hours |

Custom Solutions & Application Case Studies

- Client: Large EAF steel mill, Southeast Asia

- Solution: Supplied GPC at 0.5-5mm, with <0.05% sulfur, and pre-dried. Integrated into EAF process.

- Outcome: Carbon recovery rate increased from 92% to 98.6%, annual savings $490,000

- Client: European lithium battery manufacturer

- Spec: GPC (fixed carbon ≥99%, metals <5ppm)

- Outcome: Reduced defect rate from 3.5% to 1.1%, passed cycle testing (per IEC 61960)

- Industry-standard referenced: ISO 12965:2022, IEC 60480

- Outcome: Anodes using Luxi GPC show 27% lower wear after 6 months

"Switching to GPC from Luxi improved our melt quality and reduced graphite addition cycles, with excellent tech support."

— Foundry Chief Technology Officer, Turkey

Certifications, Partnerships & Customer Service

- Certifications: ISO 9001:2018 (Quality), SGS third-party test report (purity, S, metals), ANSI/ASTM D6376-10 compliance

- Major Cooperating Clients: ArcelorMittal, POSCO, Baosteel, Hyundai, Exide, BYD

- Service Years: Over 15 years international GPC supply experience

- Delivery Cycle: Standard 2-4 weeks from order, expedited options available

- Warranty: Full replacement guarantee for quality non-conformance; 1-year shelf life under proper storage

- Support: 24/7 tech engineers, supply chain tracking, downloadable COA & MSDS

- Compliance: Products meet or exceed EU-REACH, RoHS, ISO 12965, ASTM carbon analysis

Reference: SGS China, ISO.org, RoHS and REACH compliance reports, see ISO 12965

Technical FAQ on Graphitized Petroleum Coke & Exporting Standards

References & Further Reading

-

Carbon Petroleum Coke Market Analysis & Trends 2024:

Markets and Markets Petroleum Coke Report -

Petroleum Coke Applications in Metallurgy—Case Studies:

ScienceDirect - Metallurgical Case Study -

Industry Forum—Technical Discussion on Carbon Additives:

Steelonthenet.com Forum -

RoHS & REACH Compliance for Petroleum Coke:

EU Legal Reference

-

Premium Building Material for Round Wall Exporters, Manufacturers & Suppliers

NewsJul.30,2025

-

Top Carbon Petroleum Coke Exporters – Reliable Quality & Fast Delivery

NewsJul.30,2025

-

Premium Building Material for Round Wall Exporters – Durable, Versatile Solutions

NewsJul.29,2025

-

High Performance Tundish Dry Vibrator for Steel Casting Solutions

NewsJul.29,2025

-

First Bauxite Exporters – Leading Manufacturer & Supplier Worldwide

NewsJul.29,2025

-

Top Tundish Covering Agent Exporters – Reliable Manufacturer & Supplier

NewsJul.28,2025