Jan . 21, 2025 04:04 Back to list

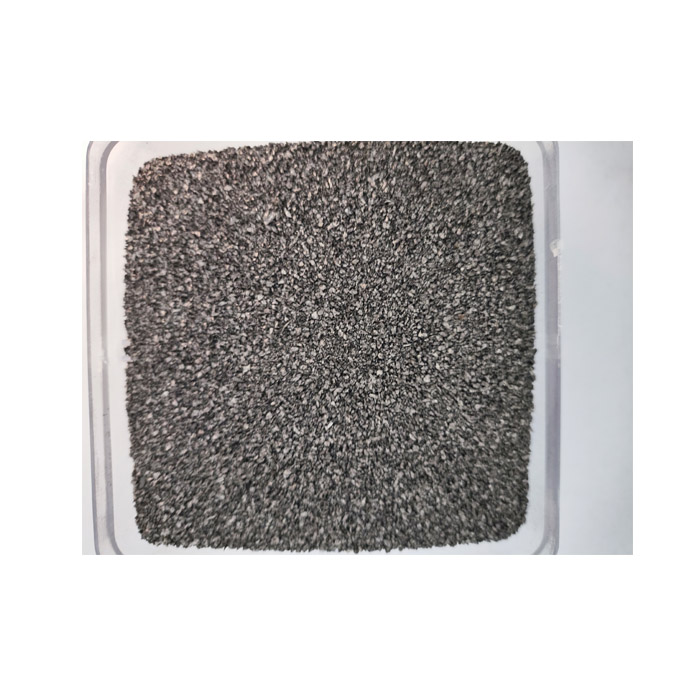

carbon petroleum coke exporters

Foundry cribs, integral to the efficient functioning of metal casting facilities, often remain overlooked in discussions about foundry operations. Yet, their role in enhancing productivity and ensuring safety is paramount. These storage solutions are designed specifically to house the tools and equipment necessary for everyday foundry tasks. Their importance is unmatched, serving as the backbone for operational effectiveness and contributing significantly to the quality of the metalwork produced.

Trust in the design and reliability of a foundry crib is built through years of proven performance and adherence to industry standards. Reputable manufacturers prioritize not just the functionality of these storage solutions but also their compliance with safety regulations. Continual advancements in material sciences and engineering contribute to the evolution of crib designs, integrating features that promote better ergonomics and increase durability. Reliability is further demonstrated through rigorous testing, ensuring each crib meets or exceeds the toughest industry demands before reaching the market. Authoritativeness in the domain of foundry crib production is established by manufacturers who invest heavily in research and development. This commitment to innovation means that these companies stay at the forefront of industry trends, adopting new technologies and methodologies that improve the functionality and safety of their products. The reputation of these companies is built on decades of experience and the validation they receive from satisfied clients across the globe who rely daily on their products. The expertise involved in effectively using a foundry crib extends to the operators and management of foundry facilities. Training staff to correctly use and maintain these storage systems is crucial. It ensures maximized productivity and prolongs the life of the tools and the crib itself. Furthermore, having experienced personnel involved in the planning and layout of cribs within the foundry floor plan can lead to more effective space utilization and process flow. In conclusion, the significance of foundry cribs in metal casting operations is clear. They provide structured storage, enhance safety, and drive operational efficiency, all while being customizable to meet the specific needs of individual foundries. As an authoritative industry component, they embody the perfect blend of experience, expertise, and trustworthiness essential for successful and safe foundry operations. Investing in high-quality foundry cribs translates directly into improved productivity and safety, ultimately ensuring that foundries can maintain high standards of metalwork quality and operational excellence.

Trust in the design and reliability of a foundry crib is built through years of proven performance and adherence to industry standards. Reputable manufacturers prioritize not just the functionality of these storage solutions but also their compliance with safety regulations. Continual advancements in material sciences and engineering contribute to the evolution of crib designs, integrating features that promote better ergonomics and increase durability. Reliability is further demonstrated through rigorous testing, ensuring each crib meets or exceeds the toughest industry demands before reaching the market. Authoritativeness in the domain of foundry crib production is established by manufacturers who invest heavily in research and development. This commitment to innovation means that these companies stay at the forefront of industry trends, adopting new technologies and methodologies that improve the functionality and safety of their products. The reputation of these companies is built on decades of experience and the validation they receive from satisfied clients across the globe who rely daily on their products. The expertise involved in effectively using a foundry crib extends to the operators and management of foundry facilities. Training staff to correctly use and maintain these storage systems is crucial. It ensures maximized productivity and prolongs the life of the tools and the crib itself. Furthermore, having experienced personnel involved in the planning and layout of cribs within the foundry floor plan can lead to more effective space utilization and process flow. In conclusion, the significance of foundry cribs in metal casting operations is clear. They provide structured storage, enhance safety, and drive operational efficiency, all while being customizable to meet the specific needs of individual foundries. As an authoritative industry component, they embody the perfect blend of experience, expertise, and trustworthiness essential for successful and safe foundry operations. Investing in high-quality foundry cribs translates directly into improved productivity and safety, ultimately ensuring that foundries can maintain high standards of metalwork quality and operational excellence.

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025