Jan . 20, 2025 05:49 Back to list

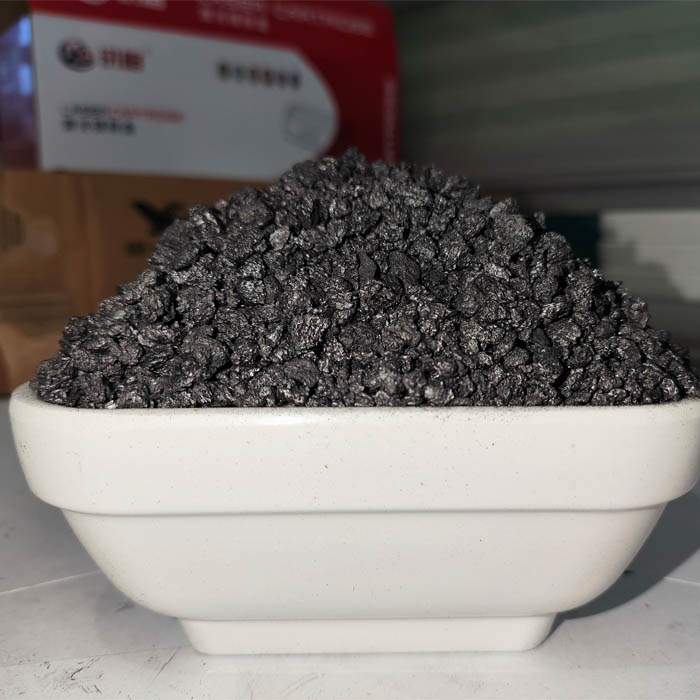

sponge petroleum coke

Sponge petroleum coke, often referred to as SPC or sponge coke, is a significant byproduct of the petroleum refining process, offering distinct properties that make it an essential material in various industries. For those seeking insights into the practical uses, benefits, and considerations of sponge petroleum coke, this article provides an in-depth exploration based on real-world experience, authoritative expertise, and a solid foundation of trustworthiness.

The handling and processing of sponge petroleum coke require specialized knowledge to maximize its benefits while minimizing potential drawbacks. As with other petroleum products, the quality of SPC can vary significantly, influenced by the source crude oil and refinery techniques used. Operators must be adept at assessing quality indices like sulfur content, impurity levels, and moisture presence to ensure optimal performance in its end-use applications. Professional insights underscore the importance of storage considerations, as sponge petroleum coke can be susceptible to moisture absorption from the environment due to its porous structure. Proper storage facilities and moisture control protocols are critical to preserving its quality, thereby preventing degradation that could affect its application efficiency. Authoritativeness and Trustworthiness in Sponge Petroleum Coke Utilization In the realm of sponge petroleum coke, authority comes from both industry-recognized standards and the ongoing advancements in refining and application technologies. Certifications from bodies such as the ISO and ASTM provide guidelines ensuring that sponge coke meets the rigorous demands of its various industrial applications. Industry leaders endorse building trust through transparency in the sourcing and processing of sponge petroleum coke. Companies that offer detailed provenance data, quality certifications, and traceability reports are better positioned to establish credibility and trustworthiness among partners and clients. Furthermore, sustainability initiatives are shaping the future trajectory of sponge petroleum coke utilization. Practices that emphasize environmental compliance, carbon reduction footprints, and circular economy principles are gaining paramount importance. Stakeholders committed to these principles not only demonstrate their commitment to environmental stewardship but also bolster their market standing as responsible players in the energy and materials sectors. In Conclusion Sponge petroleum coke serves as a versatile and economically viable material across various sectors, driven by its distinctive properties. Success in its application hinges on a comprehensive understanding of its handling, a commitment to quality assurance, and adherence to authoritative standards. As industries evolve, so too will the innovations surrounding sponge petroleum coke, promising exciting developments in renewable energy, materials science, and environmental management. By maintaining a steadfast focus on experience, expertise, authoritativeness, and trustworthiness, stakeholders can navigate the complexities of this dynamic resource with confidence.

The handling and processing of sponge petroleum coke require specialized knowledge to maximize its benefits while minimizing potential drawbacks. As with other petroleum products, the quality of SPC can vary significantly, influenced by the source crude oil and refinery techniques used. Operators must be adept at assessing quality indices like sulfur content, impurity levels, and moisture presence to ensure optimal performance in its end-use applications. Professional insights underscore the importance of storage considerations, as sponge petroleum coke can be susceptible to moisture absorption from the environment due to its porous structure. Proper storage facilities and moisture control protocols are critical to preserving its quality, thereby preventing degradation that could affect its application efficiency. Authoritativeness and Trustworthiness in Sponge Petroleum Coke Utilization In the realm of sponge petroleum coke, authority comes from both industry-recognized standards and the ongoing advancements in refining and application technologies. Certifications from bodies such as the ISO and ASTM provide guidelines ensuring that sponge coke meets the rigorous demands of its various industrial applications. Industry leaders endorse building trust through transparency in the sourcing and processing of sponge petroleum coke. Companies that offer detailed provenance data, quality certifications, and traceability reports are better positioned to establish credibility and trustworthiness among partners and clients. Furthermore, sustainability initiatives are shaping the future trajectory of sponge petroleum coke utilization. Practices that emphasize environmental compliance, carbon reduction footprints, and circular economy principles are gaining paramount importance. Stakeholders committed to these principles not only demonstrate their commitment to environmental stewardship but also bolster their market standing as responsible players in the energy and materials sectors. In Conclusion Sponge petroleum coke serves as a versatile and economically viable material across various sectors, driven by its distinctive properties. Success in its application hinges on a comprehensive understanding of its handling, a commitment to quality assurance, and adherence to authoritative standards. As industries evolve, so too will the innovations surrounding sponge petroleum coke, promising exciting developments in renewable energy, materials science, and environmental management. By maintaining a steadfast focus on experience, expertise, authoritativeness, and trustworthiness, stakeholders can navigate the complexities of this dynamic resource with confidence.

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025