Jul . 22, 2025 00:01 Back to list

First Bauxite Exporters | Top-Quality Global Supply

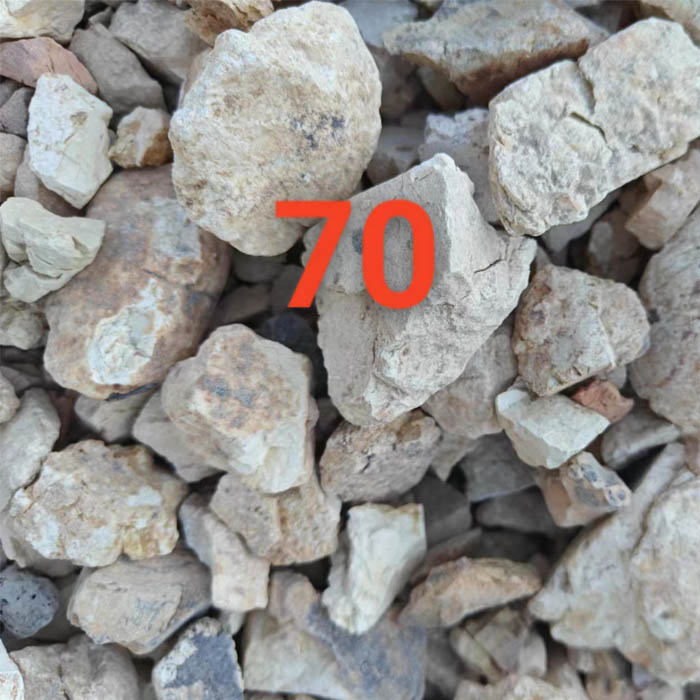

As global leaders among first bauxite exporters, we're witnessing unprecedented demand driven by industrialization and infrastructure development. Bauxite ore remains essential for aluminum production, refractories, abrasives, and chemical applications. This comprehensive market analysis examines technical specifications, evolving trends, and quality standards that define premium first bauxite suppliers.

Premium Bauxite Ore Specifications

Bauxite (bauxite ore) refers to a collective term for minerals that can be utilized in industry, mainly composed of gibbsite, boehmite, or diaspore. Xingtai Luxi delivers mineral-rich ore with industry-leading composition:

- Al₂O₃ Content: 45-88%

- Fe₂O₃: 1-25%

- SiO₂: 1-20%

- TiO₂: 2-4%

Global Export Market Analysis

Industry reports confirm expanding markets for first bauxite exporters with Asia-Pacific demonstrating 8.5% CAGR through 2028 (Mining Technology Report). Premium refractory-grade bauxite commands special pricing due to specific alumina/silica ratios and calcination characteristics.

Leading Bauxite Exporters Technical Comparison

| Parameter | Standard Grade | Premium Grade | Xingtai Luxi Special Refractory |

|---|---|---|---|

| Al₂O₃ (%) | 45-55% | 70-80% | 85-88% |

| SiO₂ (%) | 10-15% | 3-8% | ≤4.5% |

| Fe₂O₃ (%) | 15-25% | 1-5% | ≤2.2% |

| LOI | 8-12% | 5-8% | ≤1.5% |

| Bulk Density (g/cm³) | 2.5-2.8 | 2.8-3.1 | ≥3.15 |

Data sourced from International Aluminium Institute

Industrial Applications of Premium Bauxite

Refractory Industry

High-grade bauxite is calcined to produce refractory materials with exceptional thermal stability (up to 1800°C) for furnace linings

Abrasive Manufacturing

Controlled alumina content creates consistent grit for precision grinding and finishing applications

Aluminum Production

Primary material for alumina extraction through the Bayer process accounting for 85% of global consumption

Industry Expert FAQ: Bauxite Specifications

What determines refractory quality in bauxite?

The alumina-to-silica ratio (A/S ratio) is critical. Premium refractory-grade bauxite requires A/S ratio above 12:1 with controlled iron content to ensure high refractoriness under load conditions. Additional calcination transforms mineral structures for thermal stability.

What particle sizes do first bauxite suppliers deliver?

Standard sizing includes:

- 0-1mm for binder applications

- 1-3mm for tundish mixes

- 3-5mm for castable aggregates

- Custom sizing to 200 mesh

What calcination methods exist?

Rotary kilns (1500°C) achieve 1-3% LOI for refractories while shaft kilns (1200°C) produce medium-calcined ore for abrasives. Hydration resistance tests validate proper crystal transformation.

How do XRD tests verify quality?

X-ray diffraction identifies mineral phases post-calcination. Premium bauxite should show corundum as the dominant phase with minimal mullite. Gibbsite presence indicates incomplete calcination.

What are major processing contaminants?

Common impurities include quartz (SiO₂), hematite (Fe₂O₃), kaolinite clay, and titanium oxides. Beneficiation processes reduce these to required specifications.

How do bulk densities vary?

True density ranges 3.0-3.6 g/cm³ while apparent porosity of calcined bauxite falls between 3-12%. Industrial standards require minimum bulk densities of 2.8 g/cm³ for refractory aggregates.

What packaging standards exist?

1-ton super sacks with UV protection are standard for bulk shipment. Custom packaging available including 25kg laminated bags, big bags on pallets, or bulk vessel shipments exceeding 20,000 tons.

Global Supply Chain Considerations

Leading first bauxite exporters must maintain:

- Strict chemical and physical specifications across shipments

- Advanced processing technology ensuring consistency

- Strategic inventory management

- Customized logistics solutions

- Responsible mining certifications (ISO, OHSAS)

"The increasing demand for high-alumina refractories is transforming bauxite specifications. Suppliers offering consistent chemistry with advanced processing infrastructure will dominate future markets." - Refractories World Forum

Technical Reference Sources:

- Hydrometallurgy Research Journal: Bauxite Processing Innovations

- Acta Geochimica: Mineral Composition Analysis

- Refractories World Forum: Industry Standards Updates

- International Aluminium Institute: Market Reports

This is the last article

-

First Bauxite Exporters | Top-Quality Global Supply

NewsJul.22,2025

-

```text High-Performance Insulation Cup Materials Exporters | Quality

NewsJul.21,2025

-

High-Efficiency Ferro-Carbon Balls for BOF Steelmaking

NewsJul.20,2025

-

High-Quality Traditional Recarburiser Trusted Supplier & Manufacturer for Steelmaking

NewsJul.08,2025

-

High Quality Fe-C Composite Pellets Reliable Manufacturer & Exporters

NewsJul.08,2025

-

High-Quality Magnesium Silicate Adsorbent Manufacturer & Supplier Leading Factory for Adsorbents

NewsJul.08,2025